What is an emerging and promising new artificial intelligence-driven technology that can improve maintenance, quality control protocols, and operational efficiency for a manufacturing business?

Professionals working in any supply chain can attest to the importance of predictive analytics for addressing the many challenges manufacturing firms face today.

For instance, labor and material shortages can strain profit margins, and the pressure from competing firms forces prices down while speeding up the needed time-to-market for new products. Companies operating in this field must be open to new innovations in process optimization.

That’s why they are so receptive to AI-powered applications, which are seen as a critical component for future growth. One of those applications is predictive analytics (PA). Using real-time data, the PA process can predict future risks, find new ways to improve operations, and overall increase revenue for the manufacturing market.

As its name suggests, predictive analytics predicts what is likely to happen by analyzing historical data. Firms have a chance to gain better insights to make more informed business decisions.

What Are Some Applications For Predictive Analytics?

There are dozens of predictive analytics use cases in manufacturing that help you to leverage meaningful returns on investment. PA can assist multiple departments, from quality assurance to supply chain management. The following are only some of those applications.

Predictive Maintenance

Because manufacturing involves a lot of equipment and machinery, the most obvious use case for predictive quality analytics is predictive maintenance. Machinery naturally picks up wear-and-tear damage over time with use thanks to high temperatures, pressures, and constant motion.

Breakdowns can cause a variety of problems for a business and can cost upwards of hundreds of thousands of dollars. To combat the possibility, most managers use preventative maintenance measures. However, this approach is limited to only studying the current conditions and mainly guessing at future risks.

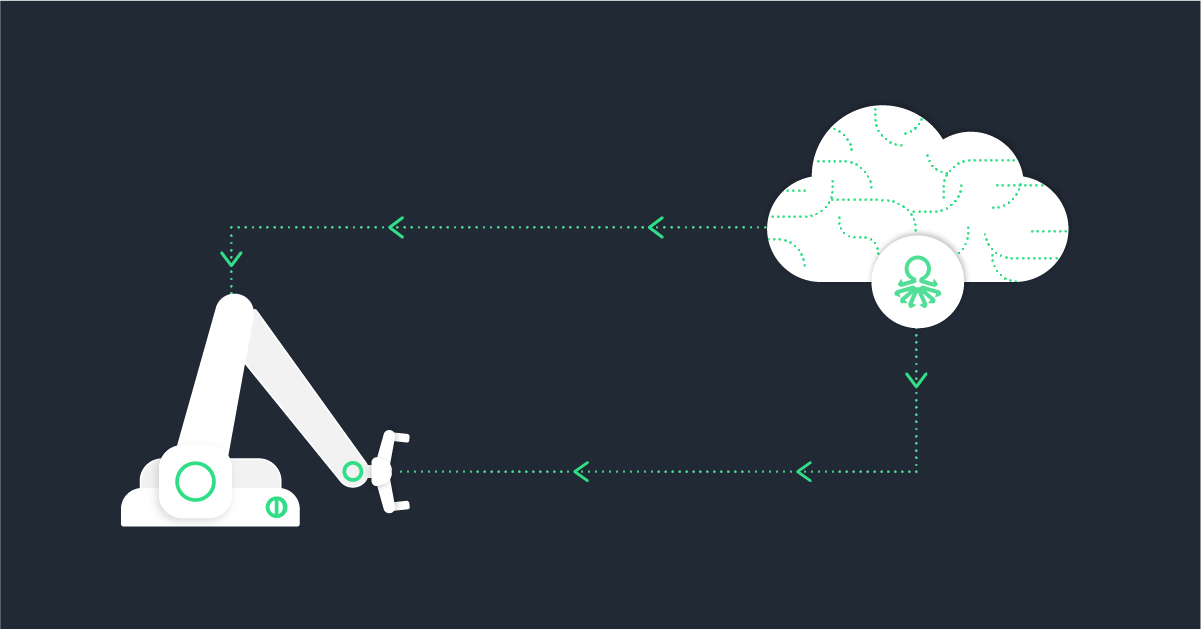

Predictive maintenance goes further. By installing real-time sensors on machinery and components, PA collects aggregate data to anticipate the chance of needed repairs and replacements. It calculates the probability of failures for each part of the manufacturing process as well as their causes.

Automation and machine learning are the cherries on top. An automated predictive analytics initiative makes the whole process seamless by notifying management of potential problems before they occur.

Market Analytics

Forecasting consumer demand is another use for PA. Knowing future demand can help you decide on what to do next.

All companies already do some form of manual market analysis. Some consumer goods, for example, are seasonal and sell better at certain parts of the year. While it’s not a new practice, demand forecasting can be empowered by predictive analytics through statistical algorithms.

There are hundreds of factors that play into determining future purchasing habits of customers, relationships with suppliers, market availability, and the impact of the global economy. Handling them all through PA is the only way forward.

Raw Material Procurement

How does your organization handle its accounting, specifically the costs of the raw materials it needs to operate? Supply costs fluctuate immensely based on seasonality and supply/demand, and the increasing cost of materials is a significant challenge for many manufacturers, as it reduces margins and forces changes in your pricing structure.

Predictive analytics can notify you of possible changes in procurement strategies, as well as reduce waste that result from ordering too many perishable goods.

Human Resources Planning

Having a smart workforce management system in place is necessary for handling skilled workers in a competitive market. So how do you predict future staffing needs and schedule training with more flexibility?

The answer lies in tracking important metrics (i.e. key performance indicators for each employee, contract negotiations, hiring trends, etc.) and using that data to determine next steps for hiring staff. Doing so is much easier with a PA solution in place.

The Challenges of Implementing Predictive Analytics

The benefits of PA are clear for manufacturing firms, so why isn’t everybody jumping on the bandwagon? It turns out that advanced analytics in manufacturing can be challenging to install into the company culture for a few reasons:

- Long lead times. AI-based predictive analytics is especially complicated. Management must prepare the data to be used, select algorithms, and test the model before deployment. Some businesses report several months to even a year for the entire process.

- Steep learning curve. PA solutions are not easy to pick up and use. Most of them are designed for data science specialists rather than regular manufacturing staff. The amount of training required might not be an attractive investment to some businesses.

- Speed. Some production lines produce products that must be available quickly (just-in-time deployment). For these purposes, low latency and real-time processing are must-haves for predictive analysis. Artificial intelligence and automation thankfully address this issue better than in the past.

- Security. The data involved in PA is sensitive in nature, so data security is something to keep in mind for cloud-based PA solutions.

Another major challenge is the ability to collect quality data, which must be elaborated on for any firm looking to weave predictive analytics into its workflow.

The Importance of Quality Data

Manufacturing data analytics is only as powerful as the data you feed it. When it comes to generating quality data, keep in mind these considerations.

- Building a data strategy. You likely have your high-level business goals decided upon, but what choices and actions do you make to contribute to those goals? Design your data strategy around those priorities to bridge the gap between tech and business effectively.

- Vast diversity of data. Manufacturing businesses often have multiple enterprise resource managers in place and different ways of manufacturing different products. Data can be shown in tables, column mappings, or any other format and can come from ERPs, MES platforms, QMS software, and other sources. Even in the same organization, it can be labor-intensive to procure consistent data.

- Consistent data. This large range of data types makes management a high priority. How do you find clear relationships between data points? Can you identify duplicates or discrepancies early on?

- Data centralization. Consolidating all your data into a single source improves accessibility. There’s a high chance another department may want access to the same data. Through a process known as data ingestion, you can extract data from various sources and transform it into a single format before depositing it into a single storage system.

Making data representative, readable, and accessible is the goal here. Predictive analytics applications typically include features like portals and dashboards to enable teams to use the resources properly.

The Role of Artificial Intelligence

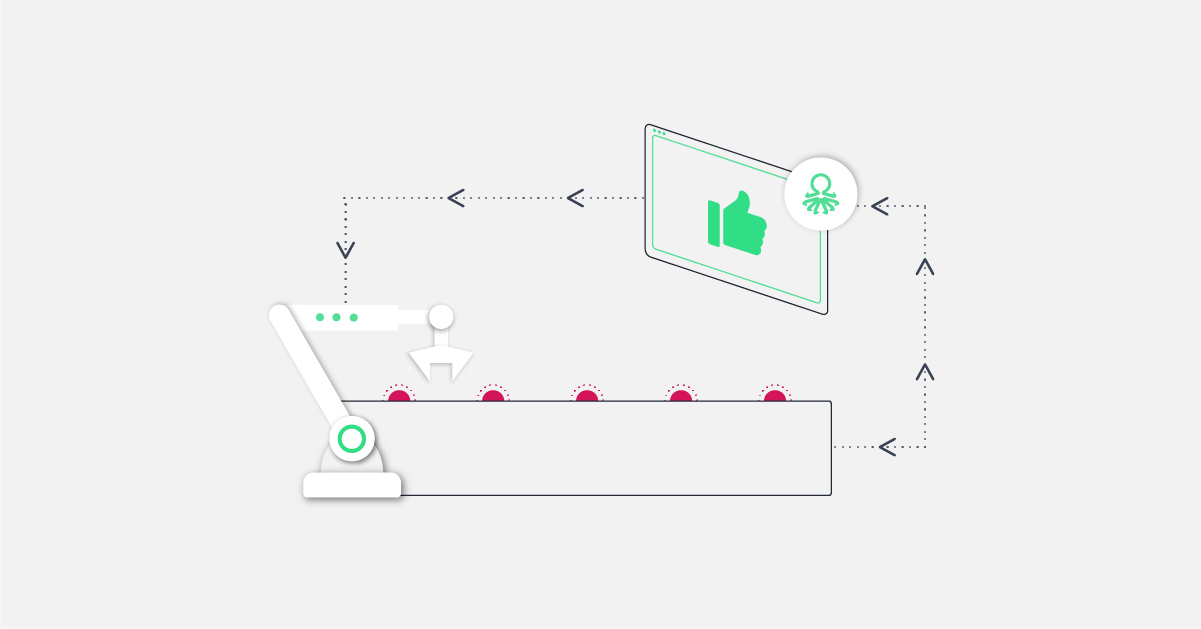

We have mentioned AI as an essential predictive analytics tool for manufacturing for good reason. AI provides the answers to the challenges we’ve mentioned above. Automatic data processing helps human staff achieve their goals faster.

Some AI solutions focus on a black-box approach, which often lacks the transparency that businesses desire. A white-box solution gives you a clear indication of how the model behaves and how predictions are created. The result is staff members becoming more confident in their decisions.

Make Predictive Analytics Fit Into Your Organization

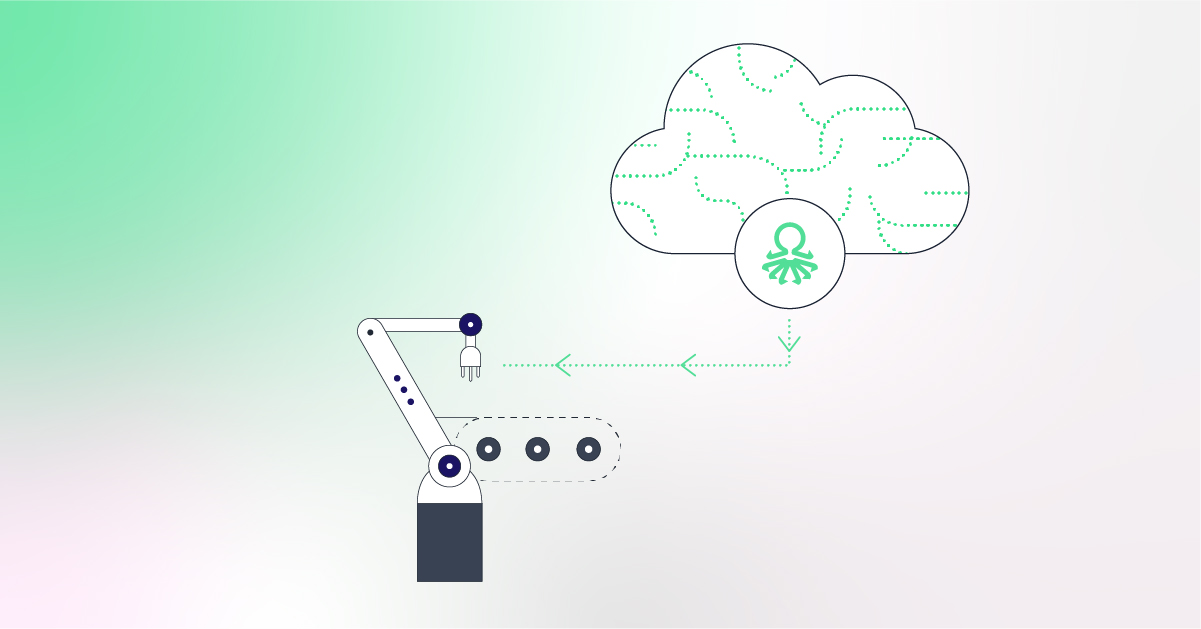

The implications of predictive analysis technology cannot be ignored by manufacturing firms. PA fits the field incredibly well too, as manufacturing always involves large amounts of data, repetitive tasks that could be automated, and solving multi-dimensional problems.

As conventional practices are becoming too slow to scale up with rising demands, adopting an automated predictive analysis solution is the key to reducing downtime and increasing efficiency in manufacturing.

Are you looking to implement predictive analysis technology into your manufacturing processes? Book a discovery call with Vanti today to get started.