Next-generation AI-powered Visual Defect Detection

Adaptive, Unsupervised, High-Volume Visual Defect Detection to Empower your Plant Floor Experts

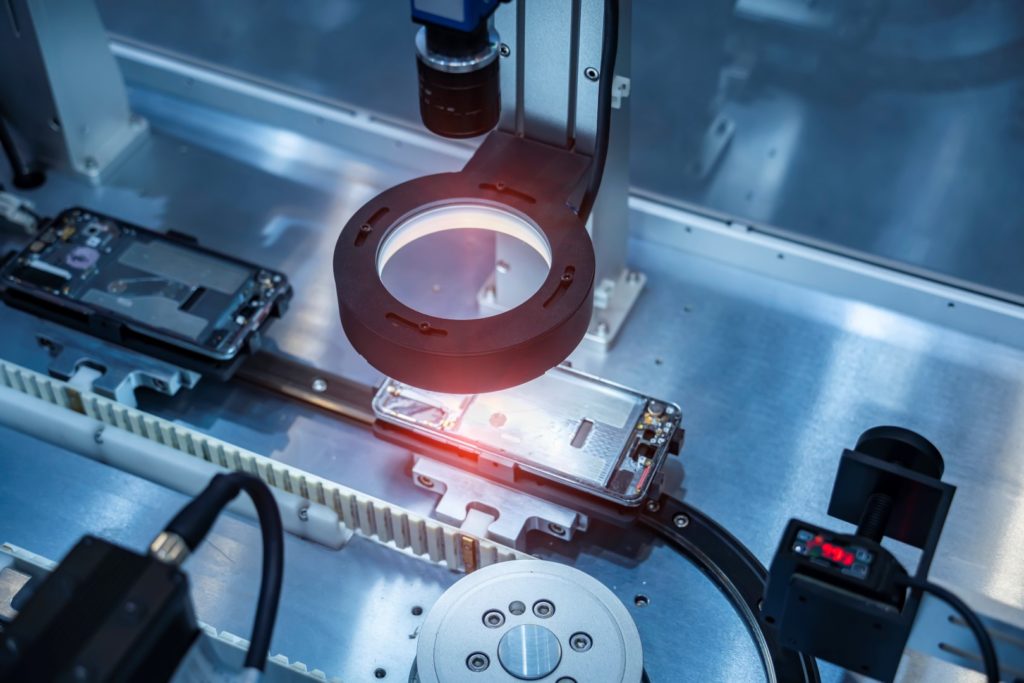

Detect Defects in High-Volume Production Lines

No Labeling Required with Unsupervised Learning

Adaptive-AI adapts to dynamic conditions

Deploy in Days, Not Months

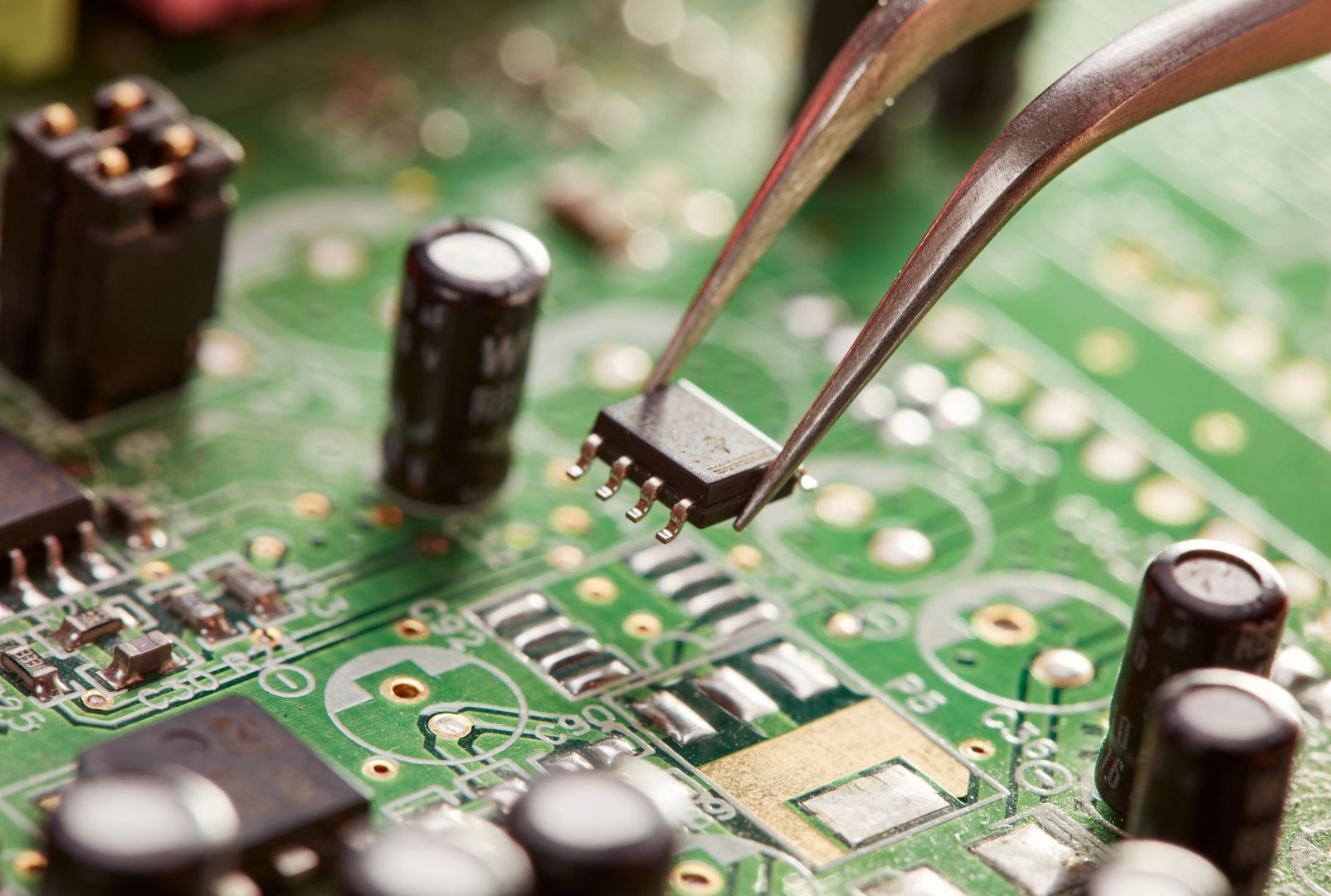

Put computer vision in the hands of your quality assurance and inspection teams. Vanti visual inspection makes computer vision with deep learning more accessible to business users by providing a straightforward collection of tools that allows anybody to label, train, and deploy AI vision models. Designed for simple and speedy deployment, simply train your model using our visual drag-and-drop interface or import a custom model, and you’re ready to activate mobile and edge devices when and when you need them.

Detect Defects at Scale

Detect and cluster defects visually at high-volumes—even new ones that cannot be labelled—in real-time to take your efficiency to another level. Predict defects accurately by automatically adapting to dynamic conditions and data drift.

Accelerate Time to Value

Realize value quickly in days, not months, by empowering your domain experts with a no-code solution that doesn’t require data science knowledge. No need to spend time on tedious data labelling—defect types are automatically clustered for review. Get going with any camera system for video or still images.

Achieve Tangible Business Outcomes

Unlock tangible business results with a closed-loop-control inspection system to significantly increase production throughput, reduce workforce effort, and improve product quality—leading to enhanced customer satisfaction.

Industry Use Cases

Semiconductor

CPG