Production Ready Industrial AI

Vanti offers AI-based solutions for manufacturers that help optimizing the production process such as detecting failures early in the process, offering faster calibration process and detecting visual defects.

SCALE

Vanti understands that any AI solution for manufacturing must be scalable, especially when working with multiple production lines. Our unique technology automatically maintains, monitors, and even optimizes models in production, so you deploy hundreds of AI models as easy as one.

Automated Model Monitoring

Vanti constantly monitors the failure rate for each model. If there’s an anomaly detected

in the failure rate, Vanti will automatically detect and notify the customer about it.

Using real-time feedback from the production line, Vanti can monitor its prediction accuracy and notify the customer or even disable predictions entirely if the accuracy drops significantly.

Vanti models can also detect data drifts. These are scenarios where the values sent are slowly changing, affecting the model performance in the long term. Vanti monitors this, actively notifies and works to offer ways for model optimization if necessary.

Data Changes Adaptation

As data constantly changes, due to changes in the unit material or in the tests themselves, Vanti models automatically adapt to these changes and maintain their predictive capabilities. Vanti

model can automatically perform backtesting, when the model essentially takes the original data that was used to train the model, changes this data to fit the new data structure (i.e. removing the column that is missing) and verifies whether the modelperformance has not changed.

Automated Model Optimization

Vanti works behind the scenes to make sure your deployed model in production is the best fit for you. Vanti constantly collects data from the production line and automatically trains new models based

on this new data (we call it “ghosts’ models”), in order to figure out if there is a model that could beat the performance of the deployed model. Ghosting ensures that the model will always perform at its best. If Vanti finds a better model, it will automatically offer you to upgrade your model to a better version.

DOMAIN EXPERTISE

Data Onboarding

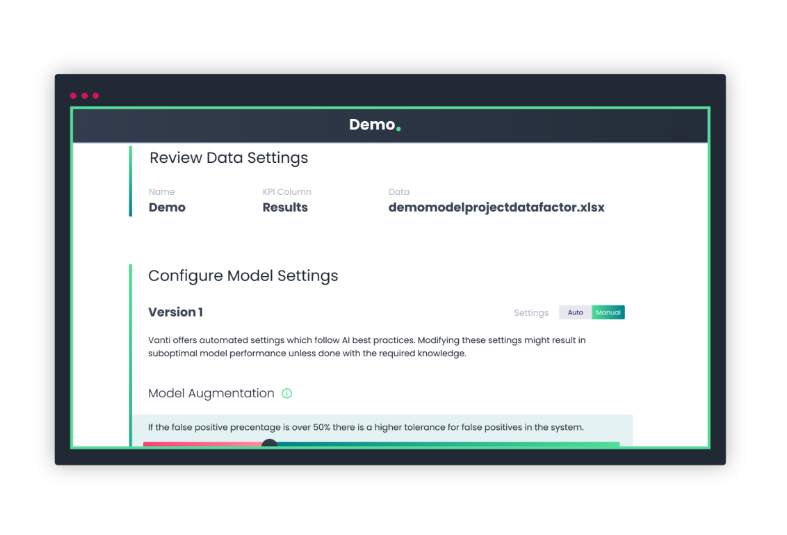

This process is designed to provide a simple user experience that requires no data science knowledge to build a model.

Rapid Deployment – Once you have the data you wish to use for the model creation, deploying a production-grade predictive analytics model can take up to a couple of hours, not months.

Domain Knowledge AI

Vanti AI model is built in a way allowing you to upload real production data where only a fraction of the units are marked as “fail” and still provide accurate results.

Moreover, Vanti models lets domain experts to configure the model in a way that will best suit their business needs.

Model Insights

Vanti models are built as a white-box, meaning they provide detailed explanations that lead the algorithm to predict whether a unit is destined to fail. This provides not only a deeper understanding of the model predictions, but also insights that shed more light on the manufacturing process as a whole.

Vanti's AI architecture on the production line

Getting Started With Vanti

Design, build, train, and deploy a production-grade prediction model in less than a day, with no technical skills required. Our onboarding and integration process is designed to be as simple as possible.

Define the use case

you want to achieve

based on the use cases

mentioned above.

Build the model using

available data (historical

and real-time).

Deploy the production model, once

the model fits your needs. You can

also train multiple models based on a

single data set with different

configurations and choose the model

that best suits your business needs.

Integrate real-time

production data with Vanti

using our standard API.

Get real-time

predictions .

Get notified if we find a model that is

a better candidate for deployment.

Discover faulty units early in the manufacturing process

See how your data can improve early fault detection faster