The decision to scale manufacturing operations should not be made without plenty of consideration. It’s always tempting to grow and expand the organization, but doing it improperly can risk the entire company.

Learning how to scale production is not a simple task. There is much that needs to be considered before undertaking this initiative, and learning what must be done is only the beginning.

Today, we’re going to discuss five tips that will help you understand everything that must be done to effectively scale. Let’s get started.

1. Keep Business Value in Mind

Scaling digital manufacturing should begin by considering the company’s overall strategy, including specific performance and financial metrics. Without understanding the goals that an organization wishes to achieve by scaling, it will be difficult to effectively scale manufacturing operations. It will be even harder to understand if specific initiatives are successful.

Once you have clear business goals that are related to how to scale manufacturing operations, you’re ready to start getting down to the logistics. Keep the focus on these goals at all times as new processes are made, new roles are created, and new sites are developed.

2. Utilize an Integrated Approach

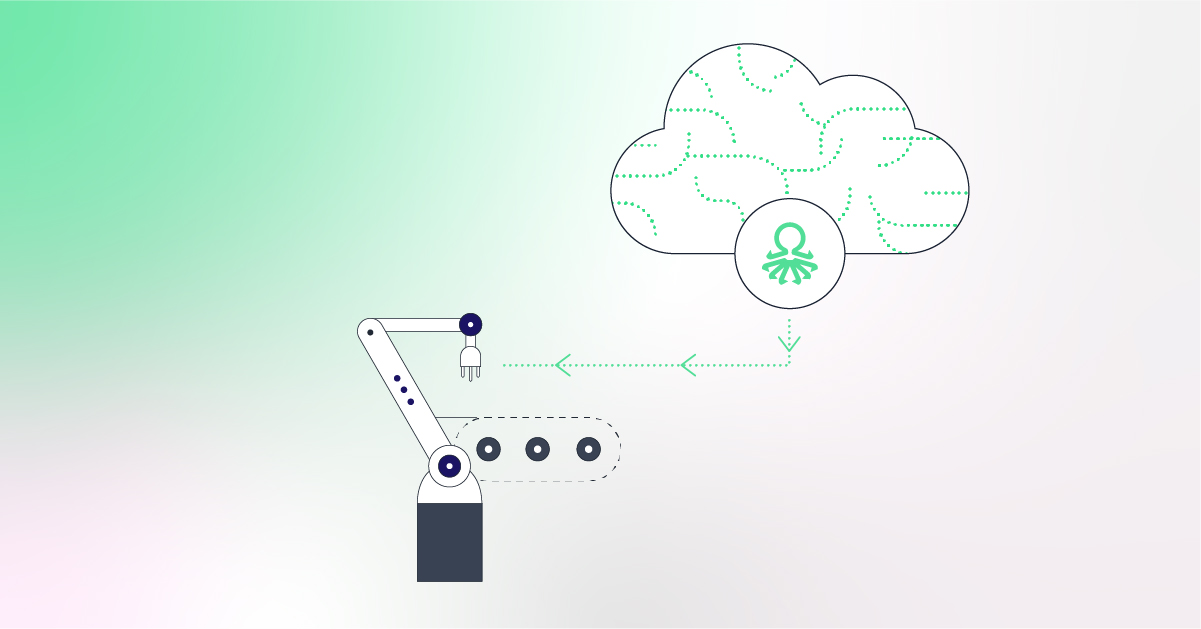

An integrated and standardized approach should be followed at every new and existing manufacturing site to facilitate digital transformation in manufacturing. Establishing this approach will call for creating several new capabilities, such as:

- Create the technical architecture to ensure future scalability, both vertically and horizontally. Horizontal scaling enables future integrations with the infrastructure, while vertical scaling means connecting more users and sites.

- Invest in developing new roles within the organization that will enable further scaling opportunities. This includes creating a reskilling and upskilling program for existing workers.

- Establish an agile product development philosophy. Create a minimum viable product, deploy it, and continuously iterate with minor changes, learning and streamlining throughout the process.

The organization will be poised for success once all of these capabilities are created. The technical infrastructure will be in place, the roles will be filled with qualified workers, and product development will be streamlined.

3. Have the Right Roles for Deployment

Manufacturing at scale calls for having the right human capital within your organization. Beyond that, you must ensure that your organization has the correct roles in existence. As your business begins to consider scaling manufacturing operations, much thought should be given to which roles will be needed.

Given several manufacturing trends that are currently in motion, it would be wise to create roles for IT architects, digital change agents, data engineers, and data scientists. You will almost certainly have new roles on the frontline as well. Some organizations have roles for people to simply translate interactions between technical experts and businesspeople.

Creating these roles further enhances the overall scalability of the business, as new sites can follow the existing template. The main task will be hiring the right people for each job, rather than making sure that the right jobs are there in the first place.

4. Plan the Architecture for Future Needs

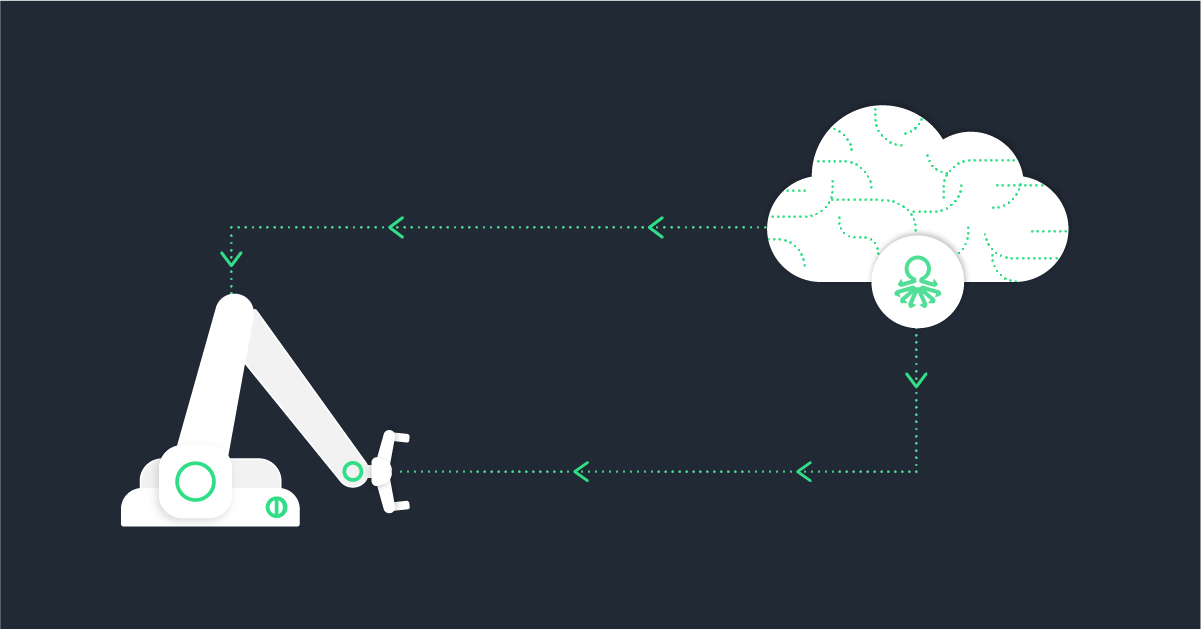

The technical architecture should be designed to consider the ongoing expansion of solutions, sites, and users. The first step in achieving this goal is developing a detailed data-driven roadmap for scaling. This highly technical roadmap will help IT professionals design the right architecture from the beginning.

An ideal forward-thinking architecture will consider critical features of use cases that are outlined in the scaling roadmap. By looking at the end goal from the beginning, IT professionals will be able to create code repositories, apps, and data pipelines that can be reused while scaling.

Making use of AI solutions for manufacturing will help create more informed decisions when planning future architecture. Artificial intelligence in manufacturing industry has exploded in recent years. IT professionals who keep the possibilities of artificial intelligence at the forefront of their planning process are poised to create an effective roadmap.

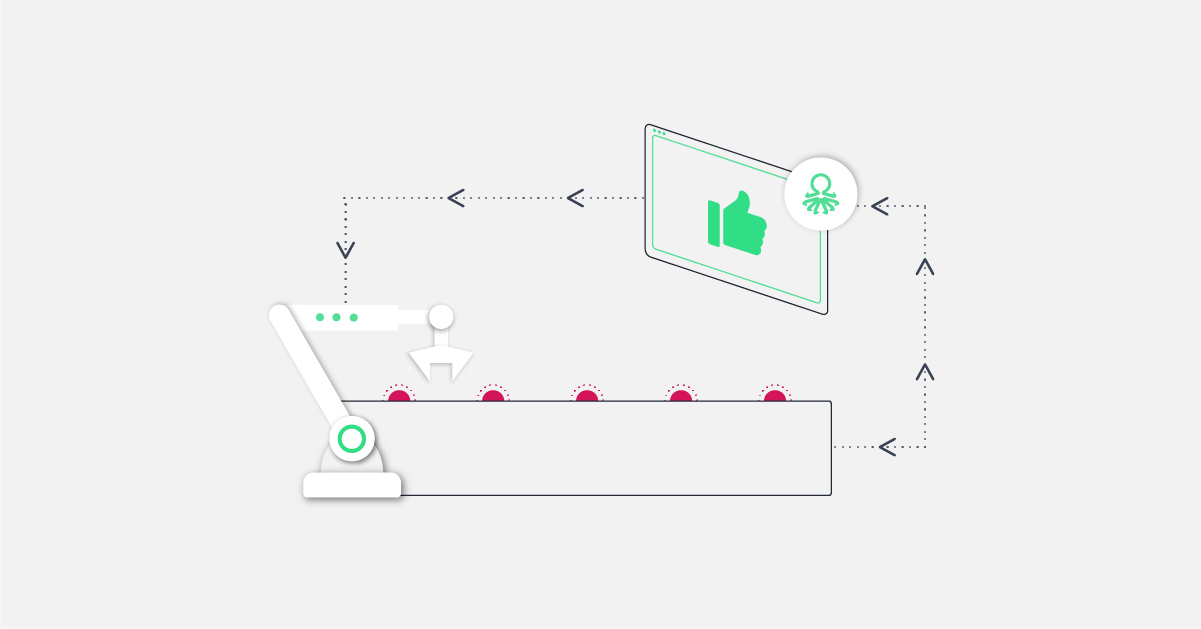

5. Analyze and Record Impact

Organizational leadership should carefully monitor the financial and operational benefits that arise as manufacturing scales. Doing so requires the ability to understand the health and performance of specific operations. Each new endeavor should be scrutinized, before and after implementation, to understand the effectiveness of the new process, product, or role.

Monitoring and analyzing the impact of scaling manufacturing operations on business goals is truly the only way to understand your organization has effectively scaled operations. Leadership must have all the information available to make informed business decisions about further expansion.

Scale Effectively and Intelligently With Vanti

Learning how to scale a manufacturing business is a complex topic with plenty of moving pieces. Keeping the focus on the business will help ensure that you do not become focused on the wrong metrics, while monitoring impact will help determine if scaling has been successful.

Of course, having the right solutions from the beginning is not just important—it’s critical to your long-term success.

Are you looking to better leverage the data you have to scale your operations? Contact us today to see how leading manufacturers are using Vanti to overcome their biggest scaling challenges.