Success in manufacturing requires constantly exploring new ways to streamline operations. In the past, this meant spending months dissecting every single process looking for ways to make that process more efficient.

Thankfully, the rise of industry 4.0 and IoT have given rise to a new way for manufacturers to assess their processes: manufacturing analytics. These specialized solutions provide more than enough data to make decisions about improving (or removing) processes.

Some manufacturing analytics software, such as Vanti, goes beyond simply reporting what’s happening and grants actionable insights in plain English. This makes discovering areas of improvement straightforward.

That’s only the beginning, however. A manufacturing analytics solution can provide manufacturers with plenty of business benefits, which we will explore in today’s post. We’ll go over how the right solution can grant insight into the supply side of the business, help monitor machines, and create earlier defect detection.

1. Have a Solid Understanding of the Supply Side

Every manufacturer must purchase supplies, but many manufacturers are too focused on other areas to gain a thorough understanding of their supply side. It’s an understandable issue since supply is not the core business function, but neglecting the supply side can create inferior products or result in more faulty units.

The right manufacturing analytics tool will help manufacturers realize the true cost of every component throughout its lifecycle. You’ll be able to track supplies from when they arrive at the facility to when they ship out on the trucks as final products.

What’s the benefit of this? One of the main benefits is that if there is an uptick in faulty units after switching suppliers, for example, it will be a simple matter to track down where the faulty materials came from. Manufacturing analytics can also find cost-saving opportunities by carefully tracking the usage of materials.

2. Learn the Effectiveness of Each Machine

Wasted time is easily one of the biggest problems that any manufacturer will face. Manufacturing chains are designed to be streamlined and efficient, but various factors can greatly reduce the effectiveness of each facility. From planned maintenance to unexpected downtime, making sure that every machine is working at its peak is of the utmost importance.

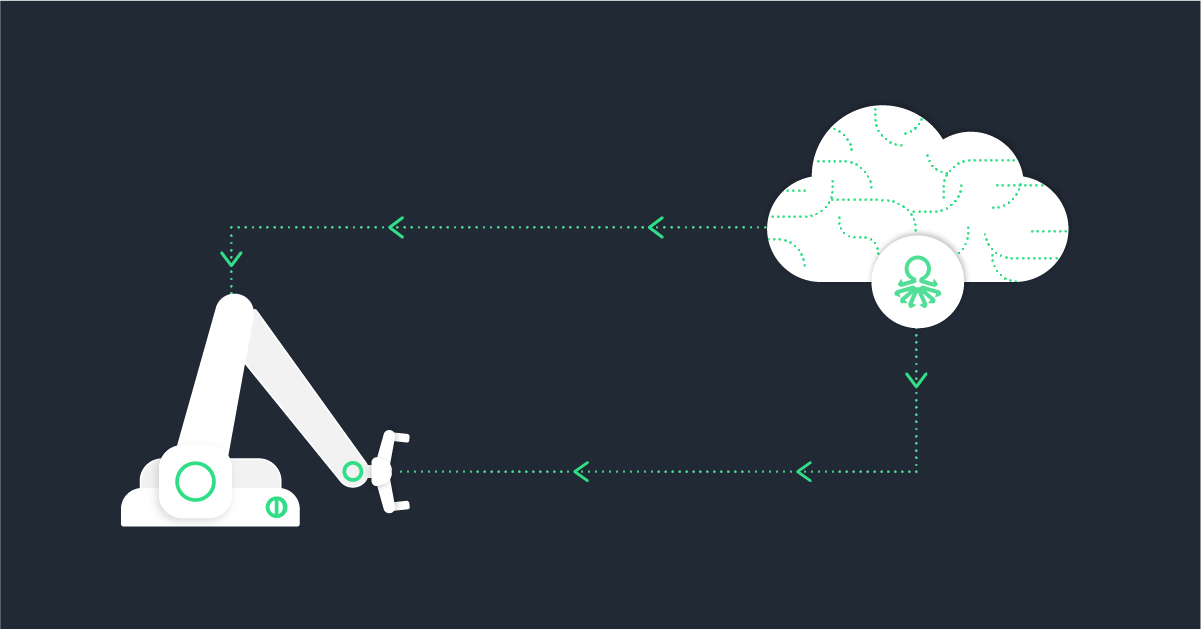

Combining predictive analytics in manufacturing with IoT systems has created a new way for manufacturers to assess how well each machine is doing in terms of production and efficiency, both on a micro and macro scale.

An ideal manufacturing analytics solution will gather all of the necessary data in real-time and generate actionable insights on demand. Looking at the manufacturing analytics dashboard is all that’s required to see which machines need servicing, which might need replacing, and which ones are performing well.

3. Earlier Defect Detection

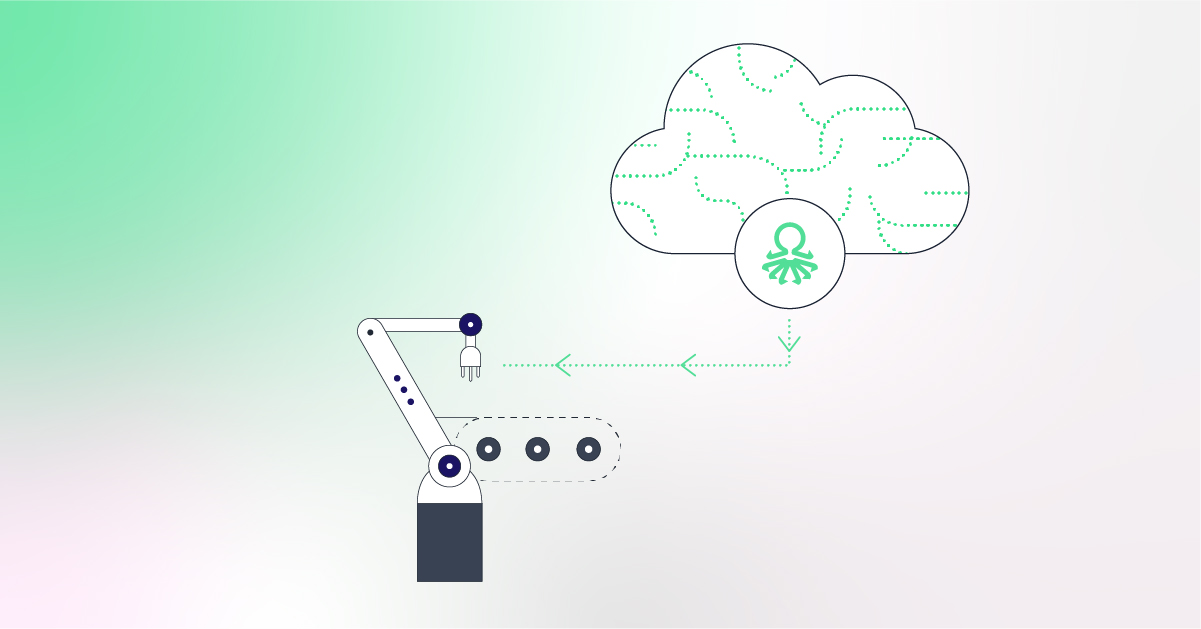

One of the most direct benefits of using a manufacturing analytics solution is creating a system for earlier defect detection. Manufacturing defect detection can help manufacturers reduce how much time and resources are wasted on further producing already defective units. If a faulty unit is detected halfway through the production process, it can simply be removed instead of being further produced.

Removing faulty units before they reach the end of the production line is one way that manufacturing analytics solutions support manufacturing product optimization. If a certain process is producing too many faulty units, a root cause analysis can be done using the analytics dashboard to help drill down into the real reason why there have been so many failures.

Defect detection was once done manually by human workers. Advancements in machine learning and artificial intelligence have transformed this paradigm. Now, advanced artificial intelligence systems make use of smart cameras and other sensors to rapidly test a product during production.

Of course, removing faulty units before they are completed saves time and resources. Looking beyond that, early defect detection also means that fewer defective products reach the end consumer. That’s something that is always good for business.

How Will Your Business Grow in Industry 4.0?

It’s clear that using real-time manufacturing analytics can radically transform a manufacturing business. You’ll understand the supply side of the business with greater clarity, you’ll understand exactly when a machine requires maintenance, and you’ll be able to detect defects before the product is finished.

All of these benefits are dependent on choosing the right manufacturing analytics solution. Vanti provides comprehensive solutions for manufacturers in all industries. Our software can integrate with your existing infrastructure to help grant you all of the above benefits.

How is your manufacturing business going to grow? Will you embrace manufacturing analytics and all of the benefits that come along with it?