“AI is the new electricity. Just as 100 years ago electricity transformed industry after industry, AI will now do the same.” – Andrew Ng, Co-founder of Coursera and Google Brain

Make no mistake, the manufacturing industry is indeed on the cusp of an artificial intelligence (AI) revolution. According to a survey by Deloitte, 93% of businesses believe that AI will be a key technology to spur growth and innovation in the industry. AI has the potential to contribute significantly to the manufacturing industry. It is estimated that the market size of AI in manufacturing will reach around USD 68.36 billion by 2032, progressing at a double-digit CAGR[. Additionally, AI is predicted to contribute an extra $3.78 trillion to the manufacturing industry. As you can see, the manufacturing industry continues to experience growth in AI adoption, with the potential to create value and improve efficiency.

It’s clear that AI is transforming the manufacturing sector. From predictive maintenance to quality control, AI-powered solutions are helping manufacturers boost efficiency, reduce costs, and achieve new levels of productivity. As we move into 2023, AI implementation in manufacturing is accelerating as companies realize the competitive advantage it offers.

In this blog post, we’ll explore the main ways AI is impacting manufacturing and provide an overview of the top AI applications manufacturers need to know about. Read on to learn how you can leverage AI to drive manufacturing excellence in the coming year.

AI for Manufacturing: An Overview

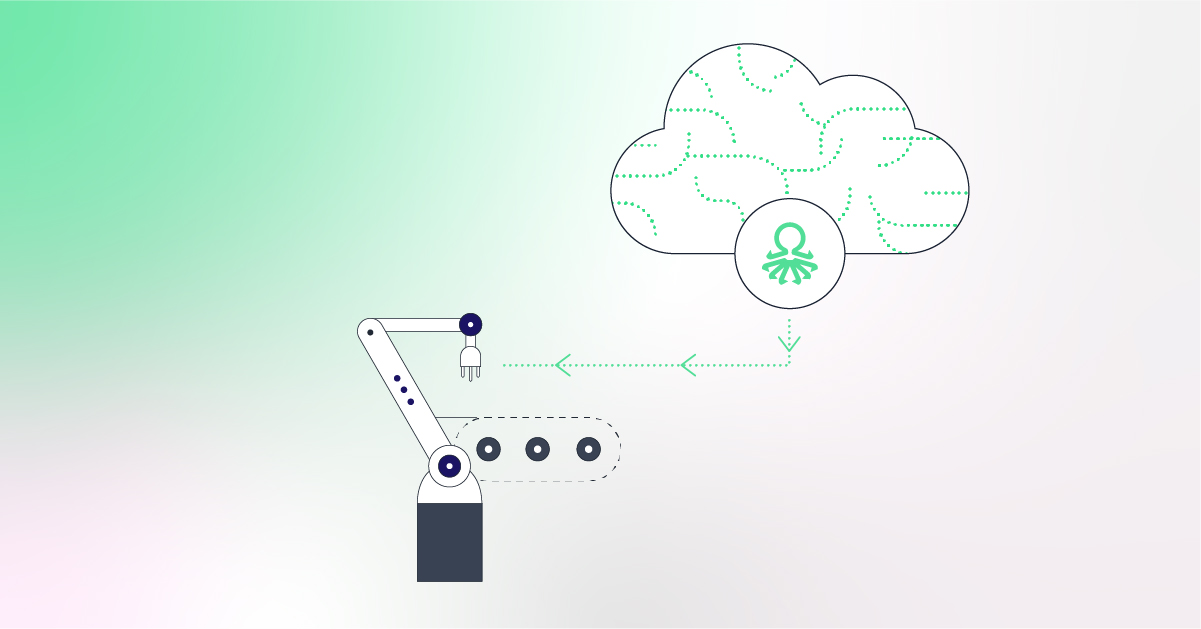

AI refers to computer systems that are designed to mimic human intelligence for performing tasks. In manufacturing, AI enables machines to sense, comprehend, act, and learn so they can perform functions traditionally done by people. AI solutions for manufacturing are revolutionizing the industry, offering unprecedented levels of efficiency and productivity.

Platforms like Vanti use generative AI to fuse disconnected manufacturing data sources into a single intuitive interface. This curates clean, unified data that can be explored through natural language, automating complex analytics tasks. AI for manufacturing is not just a concept anymore; it’s a reality that’s transforming the industry.

Some of the most common applications of AI used in manufacturing include:

– Machine learning – Systems that can automatically improve at tasks through experience without explicit programming. This includes neural networks, deep learning, and predictive analytics.

– Computer vision – The ability to extract insights from visual data, such as images and videos. Enables automated inspection and anomaly detection.

– Natural language processing – Understanding and generating human language. Allows humans to communicate with machines.x xxx

– Robotics – Robots that can automate physical tasks and interact with their environment. Includes collaborative robots that work safely alongside people.

The global AI market for manufacturing is expected to reach $16 billion by 2025, indicating the tremendous growth underway. Key drivers of AI adoption include:

– Need for enhanced quality control and reduction in defects

– Pressure to optimize supply chains and logistics

– Demand for increased speed and flexibility in manufacturing

– Shortage of skilled workers on factory floors

– Push to reduce operating costs and minimize downtime

By implementing AI, manufacturers can respond to these pressures and gain a significant competitive edge. With Vanti’s easy-to-use generative AI, manufacturers can rapidly develop and deploy AI solutions to their most pressing challenges without data science expertise.

AI in Production: Key Applications

There are countless ways AI can be applied across the manufacturing value chain. Here we explore some of the top use cases manufacturers should consider in their AI journey. AI in production is becoming increasingly prevalent, with a wide range of applications that can significantly enhance manufacturing processes.

Predictive Maintenance

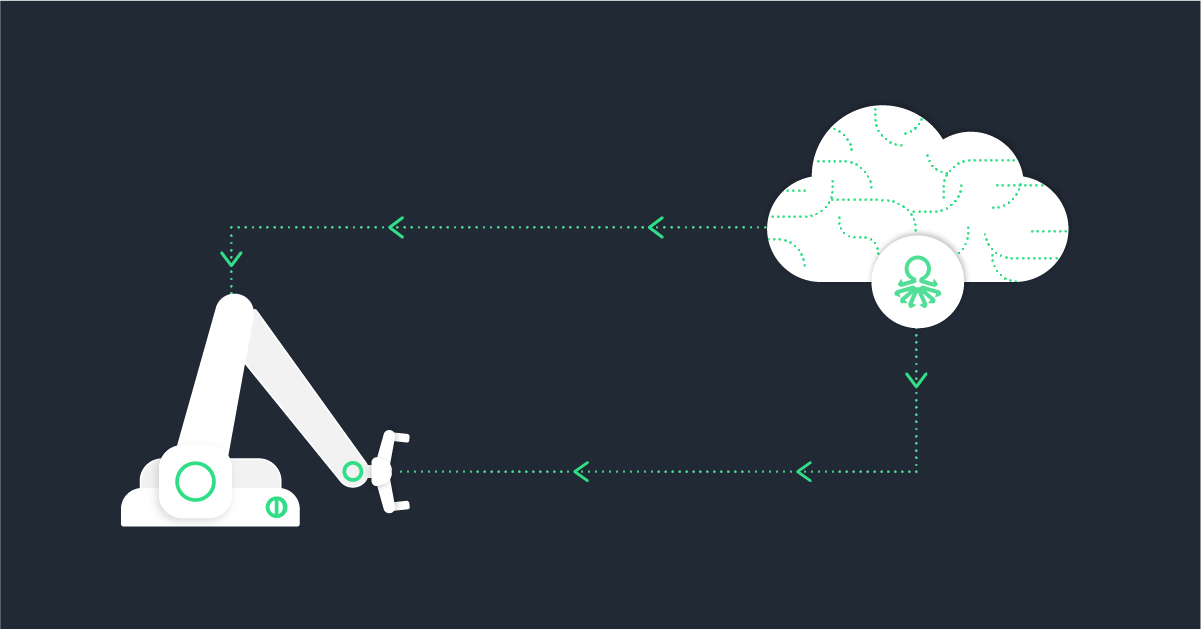

Unplanned downtime can be devastating in manufacturing operations, leading to production delays and revenue losses. AI-enabled predictive maintenance allows manufacturers to move from reactive to proactive maintenance strategies. Leveraging Vanti’s data fusion capabilities, predictive maintenance models can ingest sensor data from across machines and systems to accurately forecast equipment failures before they occur.

By applying AI to sensor data from machinery, predictive maintenance solutions can:

– Detect early warning signs of failures before breakdowns occur

– Forecast expected lifetime of equipment

– Optimize maintenance scheduling to minimize disruptions

– Reduce repair costs by addressing problems early

This improves asset utilization, increases yield, and avoids unexpected outages.

Quality Control

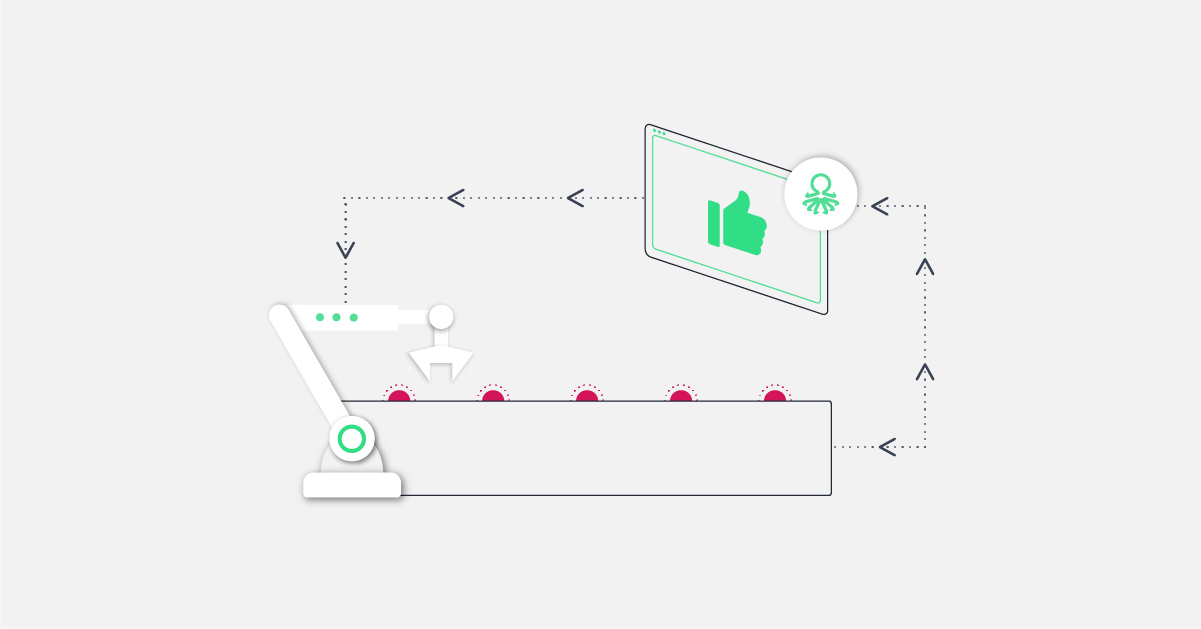

AI-powered computer vision solutions are ideal for automated quality control in manufacturing. Machine vision systems can visually inspect products on the line for any defects, inaccuracies, or assembly issues. With Vanti’s next-generation visual defect detection, manufacturers can rapidly build image classification models to identify anomalies in outputs without any coding.

This AI-enabled quality control provides:

– Faster and more consistent inspection versus human checks

– Detection of the smallest inconsistencies in outputs

– Real-time alerting so problems can be quickly fixed

– Insights to improve and optimize manufacturing processes

By leveraging AI, manufacturers can significantly reduce waste and rework due to quality issues.

Supply Chain Optimization

Manufacturing operations involve complex global supply chains. AI enables supply chain systems to predict potential disruptions and optimize logistics in real-time. Vanti allows supply chain data from ERPs, MES, and other systems to be fused into a single source of truth that can be analyzed through natural language.

With AI, supply chain technology can:

– Continuously analyze supply chain data to identify inefficiencies

– Accurately forecast inventory requirements

– Model different scenarios to mitigate risks

– Recommend optimal transportation routes and shipment plans

This improves planning accuracy, provides inventory savings, and enhances responsiveness across the end-to-end supply chain.

Predictive Analytics

AI-driven predictive analytics is invaluable for unlocking data-driven insights that support smarter manufacturing. By examining diverse datasets, predictive analytics solutions can:

– Forecast production demands with enhanced precision

– Estimate expected cycle times for orders

– Identify patterns indicating risks or problems

– Model what-if scenarios to simulate different decisions

Vanti makes predictive analytics accessible to all manufacturers through its code-free interface. Users can generate forecasts and insights instantly through natural language queries.

These predictive insights enable manufacturers to optimize production planning, increase throughput, and make data-backed decisions.

Automation with Robotics

AI-enabled robotics is automating a broad range of manufacturing tasks with precision. Robots can handle dangerous, repetitive, and high-volume production line activities around the clock without fatigue.

Key applications of robotics with AI include:

– Assembly of high-tech components and devices

– Palletizing, packaging, and material handling

– Welding, painting, and finishing applications

– Selective compliant assembly robot arm (SCARA) systems

– Human-robot collaboration for hybrid assembly

Intelligent robotics minimizes reliance on manual labor, improves consistency, and increases manufacturing safety.

Anomaly Detection

AI anomaly detection solutions analyze real-time data from sensors and equipment to identify abnormalities or outliers. This allows manufacturing teams to detect potential issues as they emerge.

For example, anomaly detection can catch:

– Critical equipment operating outside normal thresholds

– Abnormal vibrations in motors or drive trains

– Significant unexplained dips in output or yield

– Deviations from quality that require investigation

By flagging anomalies, manufacturers can prevent disruptive events and explore their root causes.

Vanti offers unsupervised anomaly detection models that can automatically learn normal behavior and detect outliers across diverse equipment.

How AI Helps Manufacturing: Getting Started

Implementing AI can feel overwhelming for manufacturers who don’t know where to begin. Here are some tips to launch your AI journey:

Identify high-impact use cases: Look for areas in your manufacturing process where AI can make a significant difference. This could be anything from improving quality control to optimizing supply chain management. Starting with a high-impact use case will help you demonstrate the value of AI to stakeholders and secure further investment.

Start small: Focus on a single pain point you want to solve rather than taking an all-encompassing approach. Quick wins build momentum. Understanding how AI can help manufacturing is the first step towards successful implementation.

Achieve ROI: Once you’ve identified a use case, work towards achieving a return on investment (ROI). This could involve reducing waste, improving efficiency, or increasing production speed. Demonstrating a clear ROI will help you gain buy-in for further AI initiatives.

Evangelize internally: Share your success stories with the rest of the organization. Highlight the benefits and improvements AI has brought to your initial use case. This will help to build enthusiasm and support for AI across the organization.

Scale across departments or regions: After achieving success with your initial use case, look for other areas where AI can be applied. This could be other departments within your organization or other regions if you operate in multiple locations. Scaling your AI initiatives will help you maximize the benefits across your entire organization.

The Future of AI in the Manufacturing Industry

AI is no longer just hype – it’s a business imperative manufacturers must embrace to build smart factories and maximize competitiveness. The rapid pace of advancement in AI means the technology will only become more affordable and accessible. The future of AI in the manufacturing industry looks promising, with AI set to become an integral part of manufacturing processes.

Leading manufacturers are already using AI for cases like autonomous quality control, intelligent predictive maintenance, AI-assisted robotics, and computer vision-enabled defect detection. In the near future, AI and machine learning will be integrated across all manufacturing processes to optimize productivity.

Vanti’s generative AI solutions are specifically designed to transform manufacturing operations by automating complex tasks and generating actionable insights. By leveraging Vanti’s no-code AI, manufacturers can quickly develop predictive models, optimize supply chains, identify defects, and more without the need for data scientists.

Now is the time to start exploring how AI can transform your operations and keep your manufacturing firm on the cutting edge. Companies like Vanti offer innovative generative AI platforms that make it easy to build and deploy AI to solve your most pressing manufacturing challenges. Reach out to discuss how our AI solutions can set your organization on the path for manufacturing excellence.