Introduction

Modern manufacturing is being revolutionized by automated optical inspection (AOI), a cutting-edge technology. AOI is a kind of automated inspection system that examines a range of products, including electronics, printed circuit boards, and medical devices. It does this by using cutting-edge image processing algorithms. To ensure that products satisfy quality requirements, AOI’s goal is to find flaws and anomalies in the production process.

Visual inspection is a vital stage in the manufacturing process that ensures the dependability and quality of the final product. The only approach available in the past was manual human inspection, but thanks to technological improvements, automated visual inspection systems have become a more effective and precise substitute.

In this post, we will contrast traditional manual inspection with the automated method, emphasizing the advantages and rewards of AOI. Additionally, we will discuss the value of visual inspection in the manufacturing sector and give a quick introduction as well.

Traditional Manual Visual Inspection Systems

For many years, skilled inspectors manually evaluated each product to find flaws and deviations from quality standards as the traditional way of visual inspection to fulfill the necessary standards in manufacturing. While manual inspection is still a viable option, there are a number of restrictions and disadvantages that can affect the process’ accuracy and effectiveness.

A skilled inspector thoroughly inspects each product as part of the manual inspection process to look for any flaws, anomalies, or deviations from the specified quality standards. The inspector determines whether or not the product is acceptable after using their knowledge and skills to spot any problems. However, there are a number of disadvantages to manual inspection that may affect its accuracy and effectiveness.

There’s always the possibility of human error, which is one of the main drawbacks of manual inspection. Despite having extensive training and expertise, qualified inspectors are still human and are more likely to make mistakes when there are more products to be evaluated. Additionally, manual inspection can produce variable results because various inspectors may use different inspection techniques. So, consistency is also an issue.

Additionally, manual examination may be costly, labor-intensive, and time-consuming. Large volumes of products may take a long time to inspect due to the slow inspection speed, which slows down the production process. This might lead to higher costs and lower production quality, which would be a big issue for businesses.

Enter Automated Optical Inspection Systems

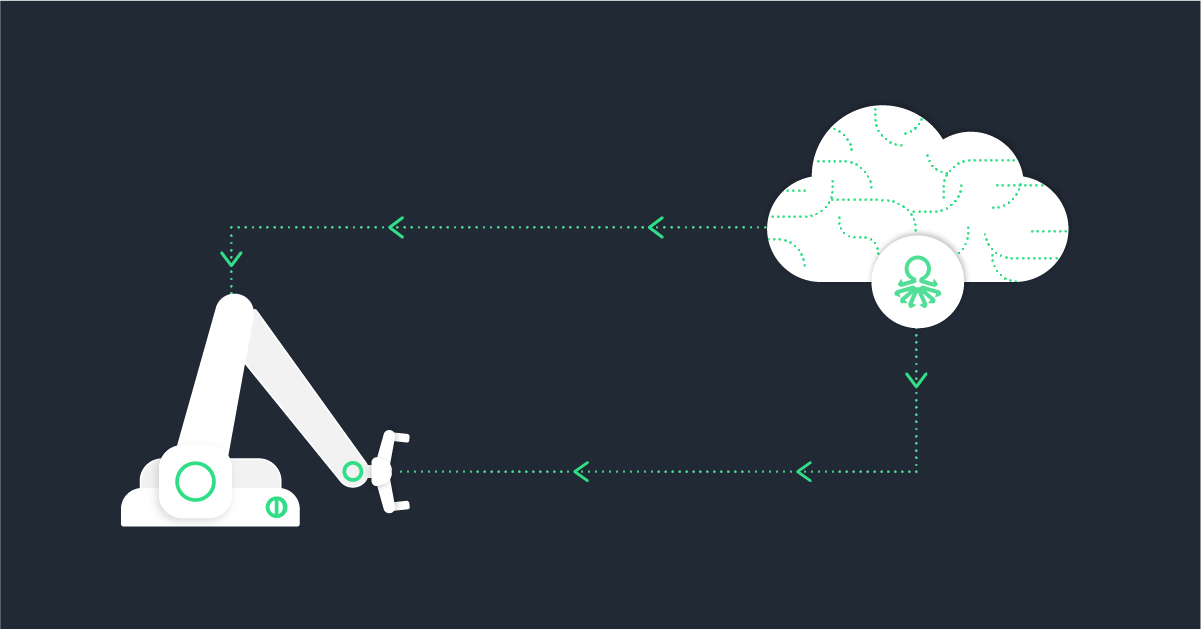

The practice of using cutting-edge imaging methods for examining and validating the quality of manufactured goods is defined as automated optical inspection. It uses sophisticated software, high-resolution cameras, and AI algorithms to automatically spot flaws, anomalies, and deviations from set quality requirements.

AOI compares photographs of the items taken during production to a reference image that is already stored in the system. The system analyzes each product image to the reference image, which serves as the ideal product, and then highlights any discrepancies or anomalies. Once the problematic product has been flagged, the system sends an alert, allowing the production process to be changed to fix the issue.

Increasing speed and efficiency, improving accuracy and consistency, enhancing production quality control, being cost-effective, and reducing human error are only a few advantages, and we will go through them in a bit more detail later. With its speedy and precise product inspection capabilities, AOI aids producers in upholding high quality standards and avoiding expensive flaws and rework.

Advantages of Visual Inspection Systems

Increased Production Speed and Efficiency:

In today’s world, where speed to market is paramount and business dynamics are changing quickly, time is money. With automated visual inspection abilities, manufacturing organizations can handle huge volumes of products in a fraction of the time needed for manual inspection, dramatically enhancing production speed and efficiency.

Improved Accuracy and Consistency:

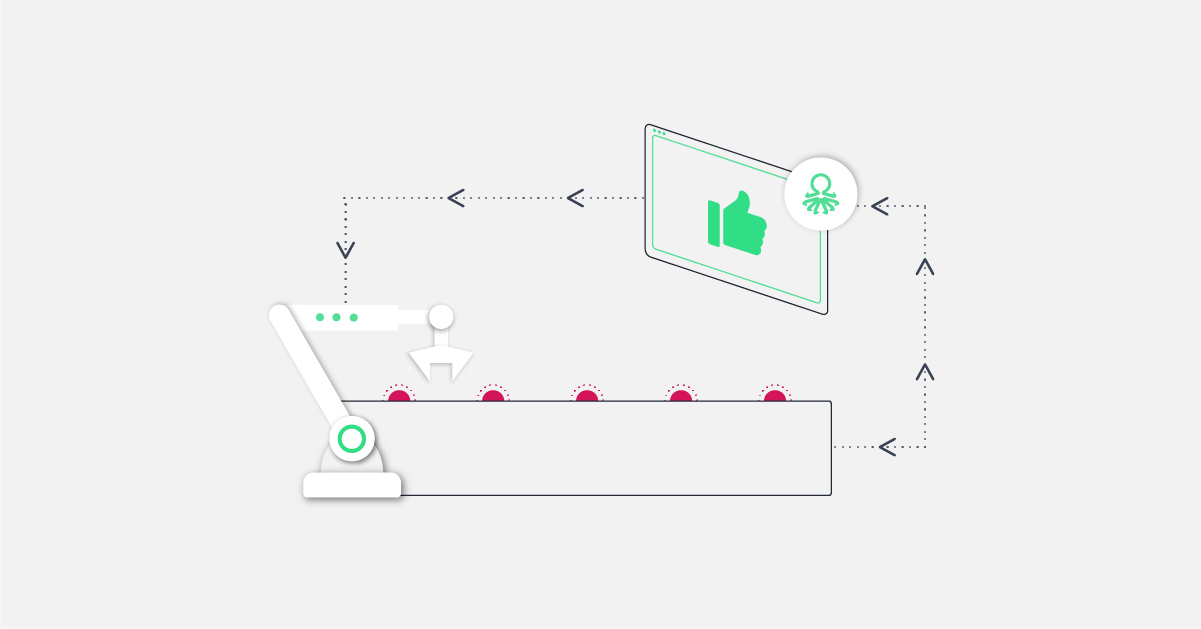

Secondly, they can quickly detect defects in manufactured products with great accuracy with computer vision and robotic technology on their side. To guarantee accurate and consistent inspection results, automated visual inspection systems use intuitive UX, cutting-edge algorithms, and artificial intelligence. The technology ensures that all items are inspected to the same high quality and does away with the risk of human mistake, which can provide uneven findings.

Enhanced Production Quality Control:

Automated visual inspection also assists in enhancing production quality control and ensuring that only high-quality products are produced by automatically identifying flaws and deviations from quality requirements. And recalls, press disasters, and customer satisfaction all improve with higher quality products.

Cost-effectiveness:

Operational cost is an important variable in manufacturing. There are many labor expenses, training costs, and error costs that can be dramatically cut with an automated inspection mechanism. While organizations may require an expert to operate and administer, automated inspection systems, they are incredibly cost-effective, as they require minimal training and operate with fewer errors than manual inspection processes.

Reduction of Human Errors:

In manual inspection processes, human errors can be a significant source of flaws and inconsistencies. While complete elimination of human error may be impossible, automation of the product inspection minimizes this risk and guarantees more reliable results. Furthermore, the system may identify and highlight errors early in the production cycle, minimizing the need for expensive rework and raising total productivity.

Comparing Automated Optical Inspection vs. Traditional Manual Inspection

Summing it up, the advantages of AOI over traditional manual inspection are easily demonstrated through comparison of key aspects such as process accuracy, consistency, speed, and efficiency.

In terms of speed, accuracy, and consistency, AOI systems provide a significant advantage over hand inspection. AOI systems inspect items quickly and precisely while reducing the possibility of human error and guaranteeing repeatable results. This results in shorter inspection times, more uniformity and accuracy, and lower costs.

The advantages of AOI systems in terms of cost and human error reduction are also substantial. The use of AOI systems lessens the requirement for manual inspection labor, which lowers labor costs and boosts productivity. AOI systems also remove the possibility of human error, which can be expensive in terms of flaws, rework, and product recalls. Because of these financial advantages, AOI systems are a sensible choice for producers who want to raise the caliber of their output while lowering the possibility of expensive flaws.

Conclusion

The manufacturing sector gains a lot from visual analytics of images and videos in the production process, including higher productivity, precision, and consistency, improved production quality control, cost-effectiveness, and a decrease in human error. For producers seeking to uphold high quality standards, cut costs, and prevent costly mistakes and rework, these advantages make AOI an invaluable tool.

In the manufacturing sector, the use of automation in visual inspections has grown in significance as consumer demand for high-quality goods and efficient production methods rises. By offering quick, precise, and consistent inspection results, lowering the possibility of human error, and enhancing production quality control, AOI systems assist manufacturers in meeting these criteria.

In conclusion, computerized visual inspection solutions are invaluable for manufacturers aiming to raise production standards, lower costs, and improve the quality of their products. AOI can assist you in reaching your objectives and staying one step ahead of the competition, whether you are a big manufacturing or a small firm.