Overview of ChatGPT and its capabilities

ChatGPT, an AI solution developed by OpenAI to converse naturally, offers exciting new capabilities in generative AI and text generation. With its advanced natural language processing, ChatGPT can summarize lengthy texts, translate between languages, and most notably, engage in nuanced conversations. This conversational ability makes ChatGPT well-suited for various ai applications in manufacturing and other industries. By understanding context and generating thoughtful responses, ChatGPT can streamline workflows, provide recommendations, and enhance processes. This is a game changer, and in this blog post, we will explore how so.

The manufacturing industry landscape and the role of AI

Let’s talk big picture first. The manufacturing industry faces pressing challenges today, including demand volatility, complex supply chains, and the need for agility and speed. AI has emerged as a solution, with its data processing strengths and ability to automate repetitive tasks. Manufacturing companies are increasingly adopting ai application in manufacturing to improve quality control, predictive maintenance, inventory management, and more. The unique conversational strengths of generative AI like ChatGPT open even more possibilities to drive efficiency and innovation.

Key Applications of ChatGPT in Manufacturing

Improving operational efficiency

ChatGPT can hugely optimize workflows in manufacturing operations. Its natural language capabilities allow it to generate reports, summarize long documents, and answer frequently asked questions. This helps automate repetitive manual processes. ChatGPT can also schedule workflows, route production, and optimize staff allocation to maximize efficiency. Rather than relying on rigid rules, it can make context-aware suggestions to improve processes.

Enhancing quality control

As one can appreciate, quality control is vital in manufacturing. ChatGPT can analyze production data to rapidly detect anomalies and defects. Its conversational ability also lets it generate detailed inspection reports, explaining the root causes of issues. ChatGPT can even recommend corrective actions to continuously improve quality control. This level of nuanced language generation is extremely useful for QA in manufacturing.

Streamlining supply chain operations

Let’s face it: managing supply chains is complex, requiring coordination across multiple entities. ChatGPT can forecast demand more accurately using a variety of data signals. It can then generate planning recommendations to align supply with demand. ChatGPT can also track purchase orders, inventory, and shipments across the supply chain. This provides greater visibility and allows AI-driven optimizations. Overall, ChatGPT can greatly streamline supply chain processes.

Optimizing maintenance and safety

ChatGPT has powerful potential to enhance maintenance and safety, which are critical in manufacturing. It can analyze sensor data to predict equipment failures before they occur and recommend preventative maintenance. ChatGPT can also generate maintenance manuals and instructions which technicians can easily follow. Most importantly, its risk analysis abilities allow it to identify hazards and suggest appropriate safety controls tailored to each manufacturing environment.

The Benefits of Using Generative AI in Manufacturing

Increased productivity and lower costs

By automating repetitive tasks, ChatGPT enables manufacturers to boost quality and output with less manual labor. This improves productivity and reduces overall costs. ChatGPT also minimizes errors that would require rework, further cutting costs. Its optimization recommendations can help identify and eliminate inefficiencies in manufacturing processes as well.

Enhanced decision making

With its analytical abilities, ChatGPT can derive data-driven insights from both structured and unstructured data. This allows more accurate demand forecasting, production planning, and scheduling. Manufacturers can make better-informed decisions at every level- from supply chain logistics to shop floor scheduling. ChatGPT can also highlight areas for further optimization in manufacturing workflows.

Higher product quality and regulatory compliance

By enhancing quality control and corrective recommendations, ChatGPT enables more consistent product quality with fewer defects. It can also monitor processes to ensure compliance with ISO, FDA and other relevant regulations. This improves product quality while avoiding regulatory penalties or recalls.

Improved worker safety and training

ChatGPT allows proactive identification and mitigation of safety risks in manufacturing plants, protecting workers from injuries. Its conversational interface also makes it an effective training tool. ChatGPT can generate safety manuals, standard operating procedures, and directly answer employee questions. This keeps workers better informed and trained.

Potential Concerns and Limitations of ChatGPT in Manufacturing

Data security and ethical risks

Like any AI system, ChatGPT comes with data privacy and security risks that manufacturers must address, although that has been addressed in the Enterprise plan squarely. However, there are also broader ethical concerns around transparency and bias in AI that warrant consideration. It is true that responsible AI practices are key to mitigate these risks.

Reliability and accuracy challenges

As an AI system, ChatGPT can “hallucinate” or make mistakes in generating text, forecasts or recommendations. It has to do with the context window of the model and how many tokens it can process. Manufacturers need quality assurance processes to validate its outputs. While advanced, it is not 100% accurate, so ongoing supervision is required.

Integration and change management difficulties

For creating maximum business value, ChatGPT must integrate into various manufacturing systems like ERPs, MES and PLCs. This can present compatibility challenges with legacy systems. Change management is also key to ensure smooth adoption across the organization. A recent Pew study showed that only 18% of Americans have used ChatGPT ever, so we still have some ways to go in terms of mainstream adoption in manufacturing.1

Emerging skill gaps and job displacement

The workforce may lack skills to optimally use AI like ChatGPT. Displacement of some manual roles is also likely, but that depends on how the leadership views ChatGPT’s potential in unlocking productivity. Proactive training and transition support for workers will be important to successfully leverage AI.

Vanti’s Pioneering ChatGPT Technology Based Offering

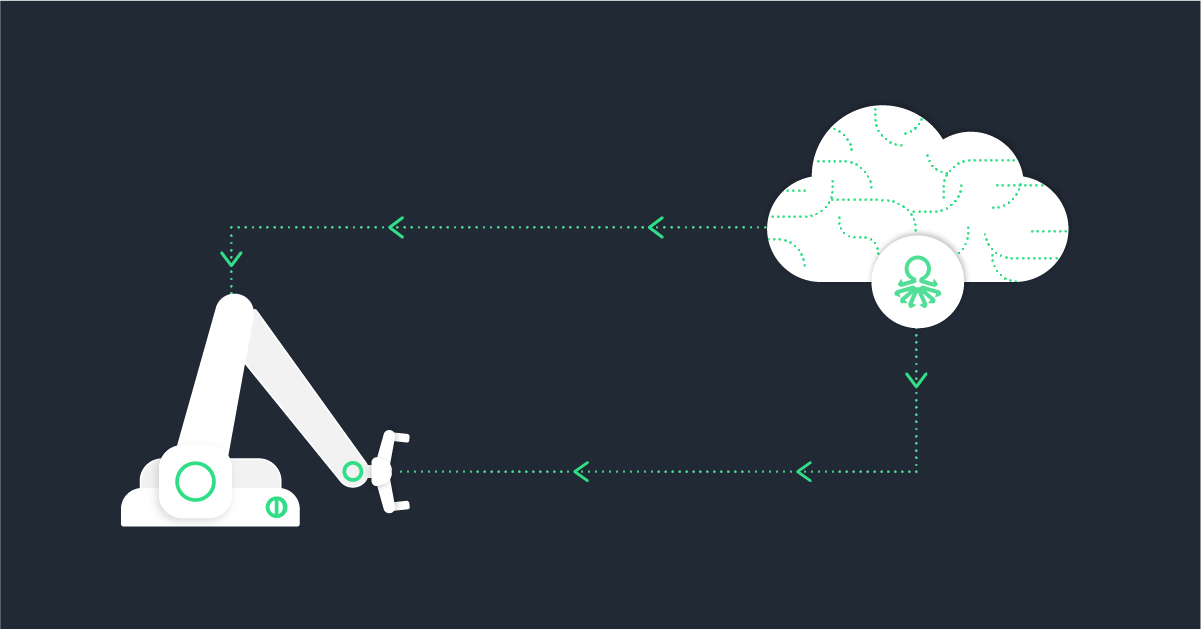

Vanti’s innovative platform is transforming industrial operations with its cutting-edge ChatGPT’s technology based Generative AI technology. By seamlessly integrating and reconciling data from multiple manufacturing sources into a unified hub, it automates the traditionally tedious and time-consuming process of data wrangling. This results in a clean, consistent dataset that is primed for analytical insights.

At its core, the platform utilizes Generative AI and natural language processing to completely redefine how professionals interact with their data. Users can simply ask questions in plain language to explore their data, streamlining analysis and enabling faster, data-driven decision making.

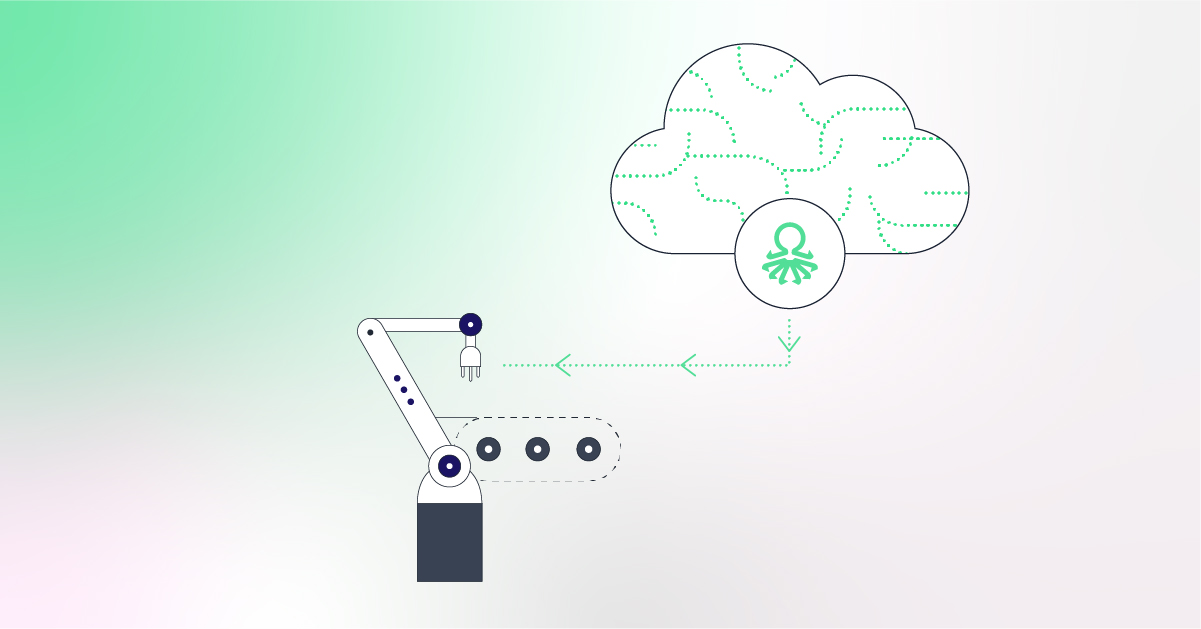

In doing so, Vanti optimizes data engineering workflows, converting week-long data projects into tasks that can be completed in minutes. Its advanced analytics provide actionable insights into plant operations by translating complex production data into clear, understandable outputs. This empowers professionals to make informed decisions backed by data, drastically improving operational efficiency and productivity.

Summing it up, Vanti’s platform is transformative, supercharging efficiency across manufacturing through the fusion of Generative AI, NLP, and cutting-edge analytics. By facilitating a deeper understanding of production processes, it promotes innovation, drives improvements, and shapes the future of industrial data management and analysis. This enables manufacturers to thrive in an increasingly dynamic, data-rich environment.

Vanti’s Generative AI Solution Differentiators

What sets Vanti apart as a unique and valuable player? The answer lies in its specialized focus and innovative approach to understanding and enhancing manufacturing processes. Here’s a closer look at the key differentiators that make Vanti a leader in the field:

Domain Expert in Manufacturing

Vanti’s expertise goes beyond just data engineering and generative AI; it has a deep understanding of the manufacturing industry itself. This manufacturing domain expertise allows Vanti to customize its solutions to the distinct challenges and prospects in this sector. By matching its technology to the particular needs of manufacturing, Vanti makes sure its AI-powered offerings aren’t simply robust but also relevant and useful. Vanti’s specialized knowledge bridges the gap between advanced AI and real-world manufacturing environments.

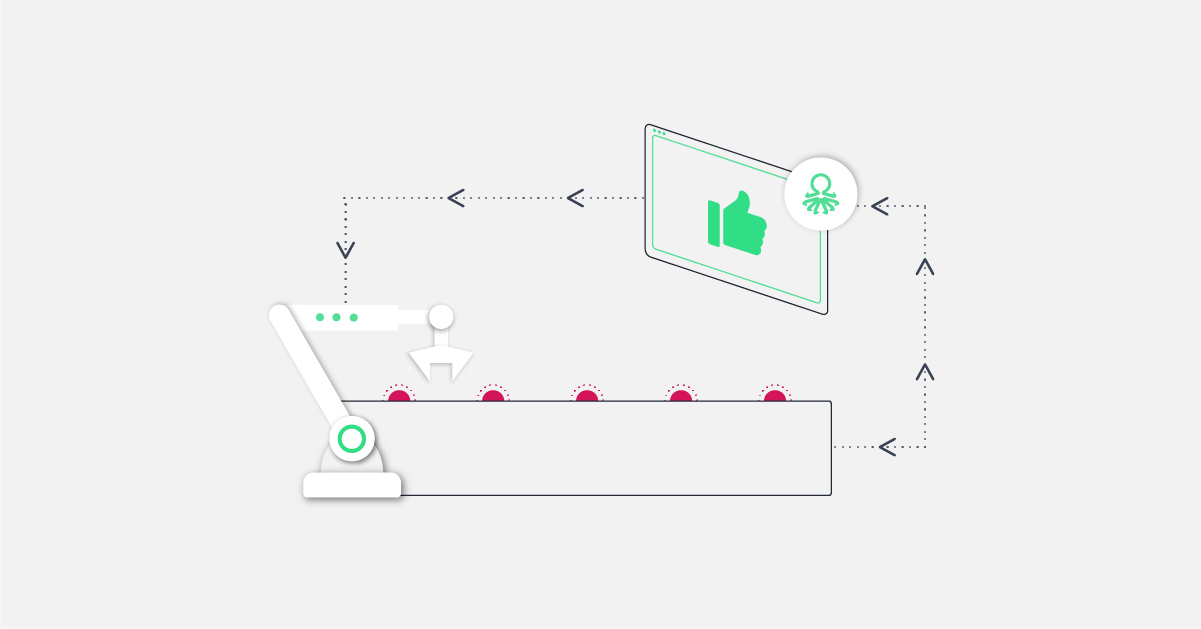

Semantic Layer Trained on Manufacturing Processes

A key advantage of Vanti is its semantic layer that is pre-trained on manufacturing workflows and terminology. Unlike general AI models that need substantial customization, Vanti’s semantic layer comes pre-loaded with an understanding of the complexities inherent to manufacturing. This manufacturing-specific foundation enables quicker deployment, greater precision, and an AI that understands the nuances of industry vernacular right out of the box. With its embedded knowledge of manufacturing concepts, Vanti’s semantic layer delivers more rapid value while avoiding the pitfalls of a one-size-fits-all AI approach.

Learns Your Manufacturing Processes Over Time

Vanti’s AI goes beyond basic manufacturing knowledge – it actually learns and tailors itself to your unique manufacturing workflows and objectives. With continuous learning capabilities, the system progressively aligns to your changing requirements and aims. Rather than a static, generic solution, Vanti evolves with you as an adaptive partner, adding value throughout your growth trajectory. It’s an AI that understands your special manufacturing needs and dynamically optimizes itself to meet them over time.

Can Work on Tabular Data

Tabular data is ubiquitous and essential in manufacturing environments. Unlike many AI solutions, Vanti is designed to integrate seamlessly with tabular datasets. This versatility enables Vanti to leverage all data types, structured or unstructured, for maximum impact. The ability to handle tabular data along with other formats underscores Vanti’s dedication to comprehensive solutions that embrace the diverse data landscape of manufacturing. It’s a reflection of Vanti’s understanding that manufacturing data comes in many shapes, and being able to use tabular data fluidly is key to unlocking the full potential of AI.

Conclusion

ChatGPT presents transformative potential for manufacturing. Its conversational abilities can drive new levels of efficiency in workflows, quality control, maintenance and more. While adoption has challenges, the benefits make its use compelling. With responsible implementation, manufacturers can leverage ChatGPT to gain a true competitive edge. The future awaits, and it’s time to seize the promise. Talk to us at Vanti and let’s shape the future together.