Introduction: The Dawn of Industrial Generative AI

Amazon CEO Andy Jassy recently said he is excited to see ‘what’s possible with generative AI’ amid the rise of tools like ChatGPT. His enthusiasm reflects a growing recognition of a new titan in the technology landscape, a titan that is poised to revolutionize the industrial sector. This titan is Generative AI, a sophisticated form of machine learning that holds the potential to reshape the way industries operate. But what exactly is Generative AI, and why is it causing such a stir in the industrial world? Let’s embark on a journey into the captivating realm of Industrial Generative AI and explore its potential.

Decoding Industrial Generative AI: A New Era in Industrial Operations

Generative AI, a class of machine learning algorithms, has the ability to generate new data samples based on input patterns. It’s akin to an artist who creates a unique masterpiece after studying various styles and techniques. In the industrial context, Generative AI can analyze vast amounts of data, identify patterns, and generate actionable insights that can enhance efficiency and productivity.

The potential of Generative AI in transforming industrial operations is vast. It can automate complex tasks, interpret intricate data patterns, and expedite decision-making processes. Essentially, Generative AI serves as a powerful compass for industries to navigate the increasingly complex landscape of the digital age.

Generative AI in Industrial Manufacturing: A Game-Changer in the Industry

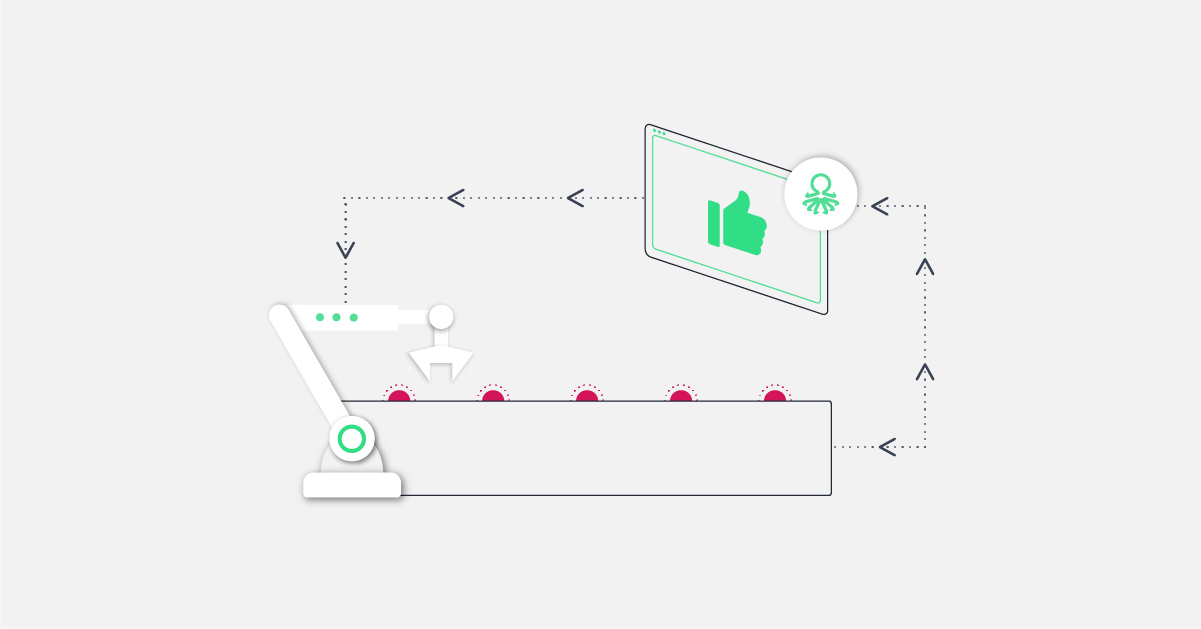

Industrial manufacturing is one sector where Generative AI is making significant strides. Here, Generative AI is not just a tool; it’s a game-changer. It can automate data fusion and curation, interpret complex behaviors for actionable insights, and accelerate hypothesis verification. This can significantly enhance the efficiency of manufacturing processes and lead to substantial cost savings.

Generative AI also plays a crucial role in predictive maintenance, a key aspect of industrial manufacturing. By generating new failure patterns and scenarios that may not be present in historical data, Generative AI can enable more accurate predictions and adaptive maintenance plans. This can significantly reduce downtime and maintenance costs, leading to improved operational efficiency.

Moreover, Generative AI can assist in optimizing the manufacturing process by generating optimal process parameters and conditions based on the desired output characteristics. This can lead to improved product quality, reduced waste, and increased manufacturing efficiency.

In addition, Generative AI can be instrumental in the realm of quality control. By analyzing historical data and identifying patterns, it can predict potential quality issues before they occur, allowing for proactive measures to be taken. This can result in a significant reduction in defective products, leading to cost savings and improved customer satisfaction.

One more way Generative AI can contribute to the development of new products. By analyzing market trends, customer preferences, and competitive landscape, it can generate ideas for new products that meet market needs and align with the company’s strategic objectives. This can significantly shorten the product development cycle and increase the chances of success in the market.

Furthermore, Generative AI can enhance the flexibility of manufacturing operations. By analyzing production data and market demand, it can generate optimal production schedules that maximize efficiency and responsiveness to market changes. This can result in improved capacity utilization, reduced inventory costs, and increased customer satisfaction.

The Impact of Industrial Generative AI on Industrial Operations

The impact of Generative AI extends beyond manufacturing. It has the potential to revolutionize various aspects of industrial operations. From design optimization to supply chain and inventory management, Generative AI can bring about significant improvements.

In predictive maintenance, Generative AI can produce new failure patterns and scenarios that may not be present in historical data, enabling more accurate predictions and adaptive maintenance plans. This surpasses traditional rule-based systems, which are limited to known patterns. The ability of Generative AI to generate new failure scenarios can help firms train and test predictive maintenance models more effectively.

In design optimization, Generative AI utilizes artificial intelligence (AI) and advanced algorithms to automatically generate design solutions based on specific input criteria and constraints. Instead of creating a single design manually, generative design explores a vast number of potential solutions to a given problem, taking into account factors such as materials, manufacturing processes, performance requirements, and cost constraints.

In supply chain and inventory management, Generative AI creates simulations of potential supply chain scenarios, helping organizations to identify risks, bottlenecks, and inefficiencies. This provides greater value than traditional forecasting and inventory management methods that rely on historical data alone. Generative AI-driven supply chain management solutions leverage data from across supplier ecosystems to deliver corrective and preventative action.

In the field of asset performance management, Generative AI with a natural language processing user interface produces context-aware responses and explanations that can be found effortlessly, eliminating the need for data engineering or coding skills. This generates an extensive amount of data, potentially leading to challenges in accessing the necessary information promptly. Generative AI is being used to develop chatbot services designed to facilitate conversations between operators and data, enabling them to assess assets and receive guidance on addressing emerging issues.

Generative AI has the potential to revolutionize industrial operations. Adopting natural language interfaces can serve as an initial step for industries to integrate generative AI into their systems, helping to contextualize data. To fully harness generative AI’s potential and usher in a new era of industrial operations, industries must address challenges such as data privacy, overfitting, and bias – all while preparing their workforce for transformations. By promoting collaborative efforts, offering continuous learning opportunities for employees, and proactively investing in generative AI integration, industries can ensure a smooth transition to an AI-driven landscape. Embracing generative AI will pave the way for increased automation, efficiency, and adaptability, ultimately shaping a more innovative and competitive future for industries.

Industrial AI Software: Vanti’s Pioneering Generative AI Offering

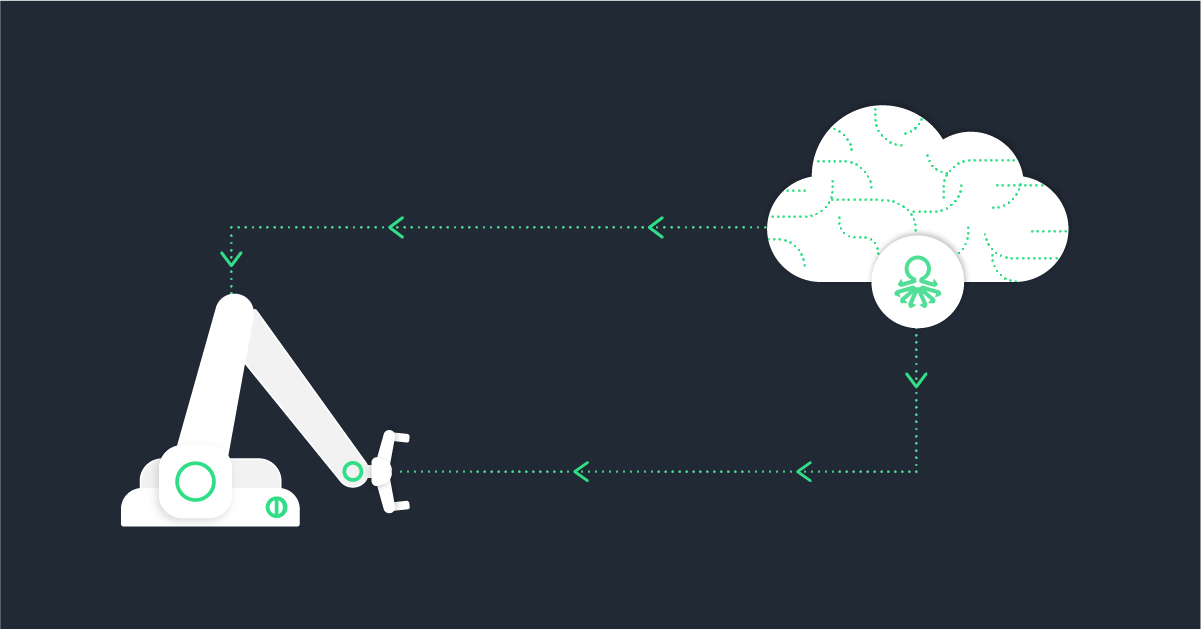

Vanti’s platform is revolutionizing industrial operations with its innovative Generative AI offering. It seamlessly integrates manufacturing data from diverse sources into a unified data hub, automating the data curation and reconciliation process. This ensures a high-quality, consistent dataset that’s ready for analytical processing.

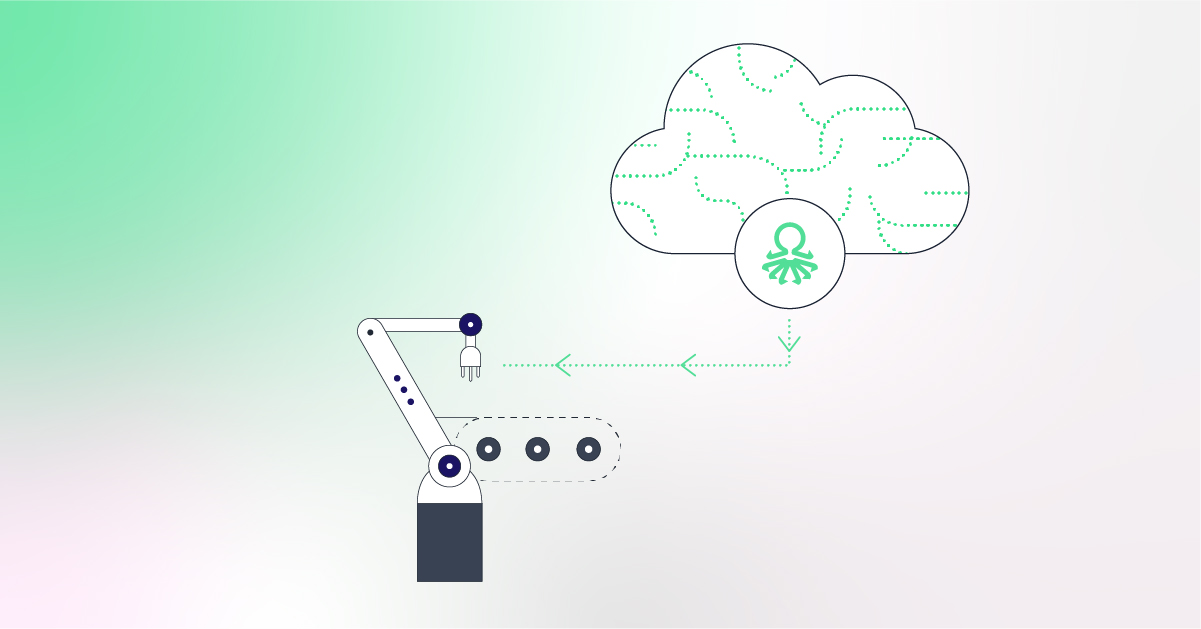

The platform leverages Generative AI and natural language processing (NLP) to transform how professionals interact with their data. Users can ask questions and explore their data through simple, conversational queries, simplifying data analysis and enabling faster, smarter decision-making.

The platform optimizes data engineering procedures, transforming week-long projects into tasks that can be accomplished within minutes. Its sophisticated analytics provide comprehensive insights into plant operations, translating complex production data into clear, understandable results. This empowers professionals to make informed, data-backed decisions, significantly enhancing overall operational efficiency and productivity.

Summing it up, Vanti’s platform is a game-changing platform that enhances efficiency across the manufacturing landscape. By fusing Generative AI, NLP, and advanced analytics, it provides a deeper understanding of production processes, fostering innovation and driving improvements. This platform is set to shape the future of industrial data management and analysis, enabling industries to thrive in an increasingly dynamic and data-rich world.

Conclusion: The Future of Industrial Operations with Generative AI

The potential of Generative AI in revolutionizing industrial operations is immense. It can serve as a powerful tool for industries to navigate the increasingly complex landscape of the digital age. With Generative AI, industries can enhance efficiency, drive innovation, and shape a more competitive future.

As we move forward, the role of Generative AI in industrial operations is certain to grow. It’s not just a trend; it’s a revolution. And those who embrace this revolution will be the ones who shape the future of industrial operations. So, are you ready to explore the potential of Generative AI in your operations? The future is here, and it’s powered by Generative AI. Let’s talk about how we can harness this power together.