Vanti has just released our newest platform update, including exciting new features for model training, user interface, and user experience improvements. Read all of the details below.

New Site Management Features

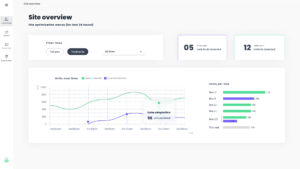

New Site Level Dashboards

The Vanti platform now includes advanced dashboards that can display individualized real-time production overviews for any user. Using these dashboards, anyone in the organization, from the c-suite to facility managers, will have visibility over all production line and facility AI metrics, from individual facility efficiency down to specific station data.

Added groupings and labels for both products and lines

The Vanti platform now allows users to group and/or label specific models, stations, and lines, enabling them to filter out all non-relevant data.

Groupings and Labels In Action:

The addition of groupings and labels allows users to view only the stations that fall under their responsibilities. As an example,

- VP and C-level executives can view real-time snapshots of efficiency, quality, and throughput.

- Facility managers can group production line stations to visualize inline data better.

- Quality managers can group data by model type, such as unsupervised defect detection.

New Advanced Analytics Modeling

Added Time Series Insights

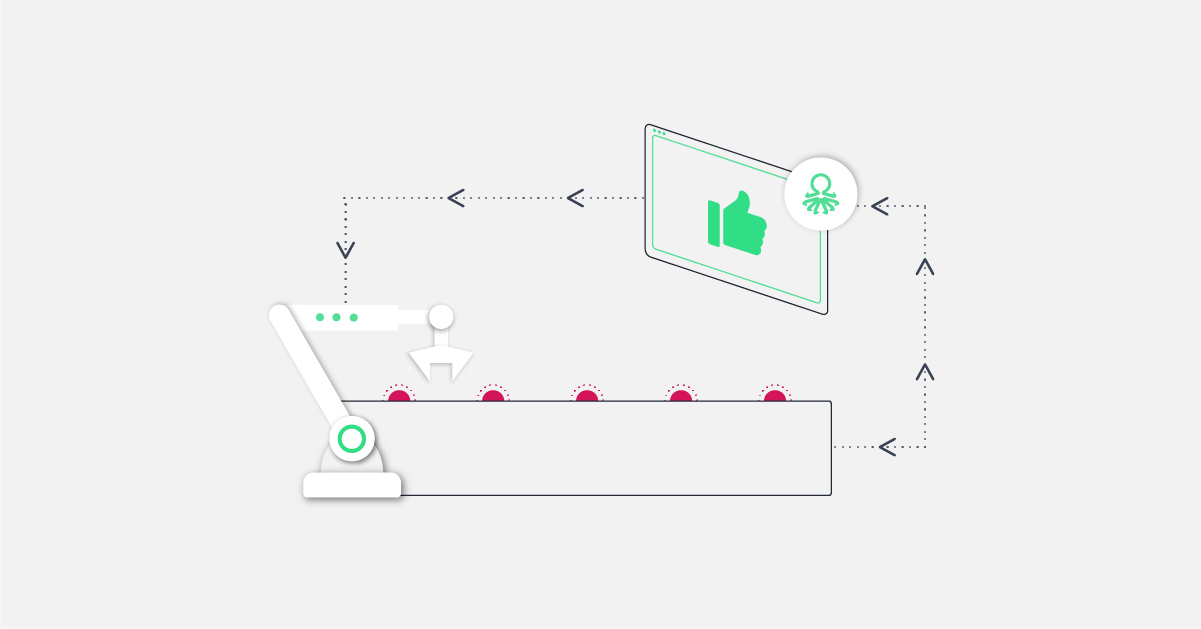

The addition of Time Series Insights enables all of Vanti’s AI models to become even more accurate by adding an additional layer of actionable insights to the Vanti platform’s built-in manufacturing AI. This layer provides the context of when actions occur, allowing models to understand correlations between station data and real-world aspects of when those data points occur.

Time Series Insights In Action:

A company built and trained an AI model for a production line that includes a 5-minute process that includes heating and cooling. The production line has a 20% defect rate, and while it’s clear the temperature fluctuations are creating the defects, there was no way to improve the defect rate further without the added dimension of time.

When training the model using the Vanti platform, Time Series Insights enables the platform to see that 15% of problems result from the temperature rising above a specific threshold between minutes 1:35 and 2:54, and another 5% of problems result from the temperature dropping below a second threshold between minutes 3:45 and 4:45.

By leveraging these insights to more effectively control the temperature, the production line can reduce its defect rate by 45%.

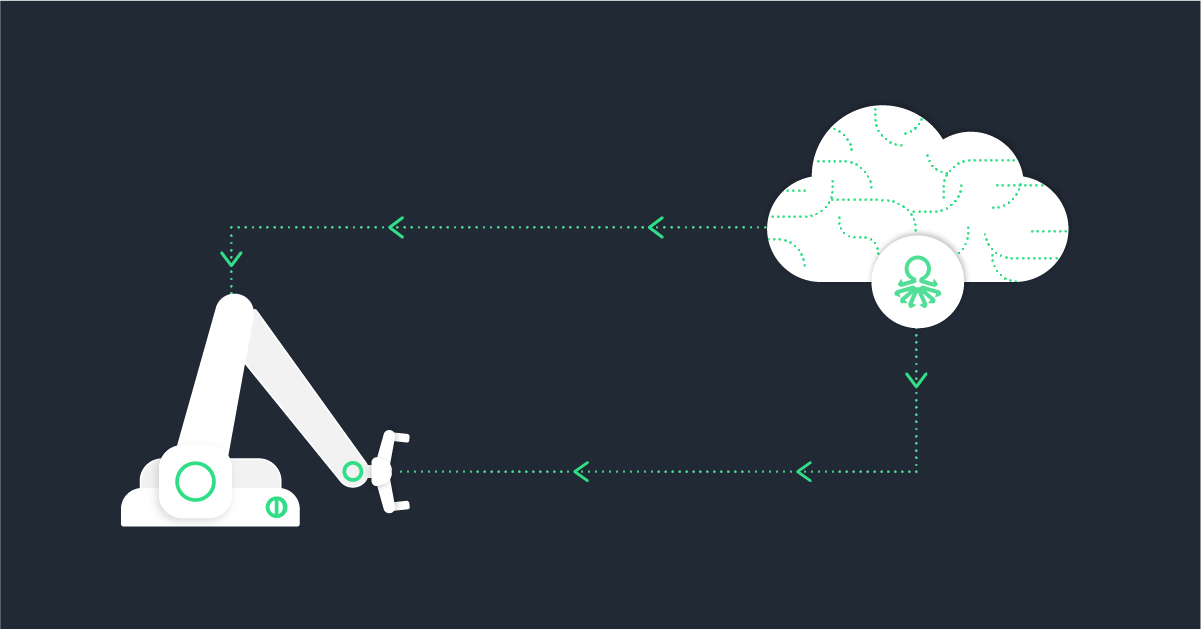

Enhanced Model Training

Vanti’s platform now automatically verifies that you’ve trained the most effective and accurate model. When training any model, the platform reanalyzes the dataset and then uses varying configurations of the data, the model, or the process, comparing accuracy with up to a hundred different production-ready models. If the platform finds a more successful model, it will allow the user to immediately deploy the new model into production.

Enhanced Model Training In Action:

When training any model, the user selects a series of variables that relate to the desired function for the model. In parallel to this training, the platform also reanalyzes all training data to achieve a higher accuracy rating. Improvements in accuracy are achieved by finding new correlative relationships between variables by applying varying configurations of the data, the model, or the process. If the platform cannot find a more effective configuration, the user will receive the model they requested. But if the platform can find a more effective configuration, the platform will provide the user with two production-ready models; the original model and the new model created by the platform.