Introduction: The Future of Manufacturing with AI-Powered Production Optimization Software

Manufacturing has long been a pillar of economies all over the world, supplying goods and opening employment opportunities. The industry has, however, recently had to contend with many difficulties, such as escalating rivalry, rising costs, and demands for greater sustainability and efficiency. In reaction to these, manufacturing leaders are turning to new technologies and approaches to optimize their operations.

No-code production optimization software with AI capabilities is one of the main technologies of Industry 4.0 imperative. This software can give subject matter experts, like plant managers and manufacturing executives, the power to improve production methods and get better results. These platforms can assist manufacturing professionals in addressing common pain points like quality control, output efficiency, and cost optimization by utilizing the power of artificial intelligence.

In this blog post, we’ll look at the advantages of production optimization software and the main challenges that plant managers and manufacturing executives encounter daily. We will also explore how AI-powered no-code platforms can empower subject matter experts and help solve these pain points. We will also go over particular applications of production optimization software in various sectors, including CPG, semiconductor, automotive, and pharmaceuticals. In our final section, we’ll present Vanti, a top supplier of no-code AI platforms created for manufacturing professionals and talk about the company’s distinctive value proposition.

Pain Points for Manufacturing Leaders and Plant Managers

Leaders in the complex and cutthroat production industry must continually look for new chances for expansion and advancement. This is not without difficulties, though, and there are some significant roadblocks that may prevent achievement. Quality control presents one of the biggest challenges for manufacturing leaders because it is crucial for customer satisfaction and a positive market reputation that products satisfy high standards of quality. If done mechanically, performing quality assurance checks can be a costly and time-consuming process.

Production efficiency is also a significant pain point for manufacturing leaders because it is challenging to optimize production flows and cut cycle times when there are numerous stages and components in a production process. As a result, manufacturing costs might go up and profits might go down.

Another important area of emphasis for factory executives is the reduction of production costs. Strict cost control is necessary to maintain a competitive edge and a healthy bottom line in a dynamic market, but any efforts to cut costs must be made carefully to maintain high quality goods and happy customers.

If these problems aren’t fixed, they could jeopardize the success of a production company. Ineffective processes can cause missed deadlines, excess inventory, and increased costs, while careless quality control can cost you clients and damage the reputation of your business. Ineffective cost minimization puts the company’s continued existence and low profits at danger.

Empowering Subject Matter Experts with Manufacturing Optimization Software

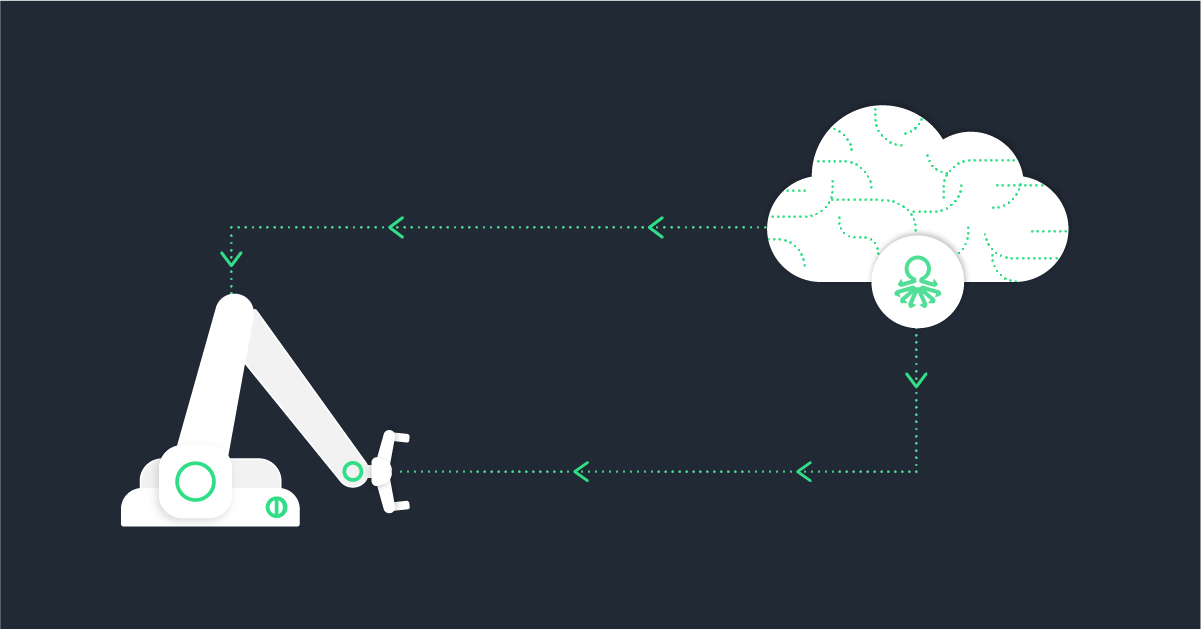

While manufacturing executives and plant managers encounter several difficulties in running their businesses daily, fortunately, AI-driven no-code platforms can give their teams the tools they need to meet these obstacles and improve their production methods. What’s great about it is that manufacturing workers can benefit from artificial intelligence without having to have a deep understanding of coding or data science. Without the need for specialized technical skills, subject matter experts can build and implement AI models tailored to their particular use case.

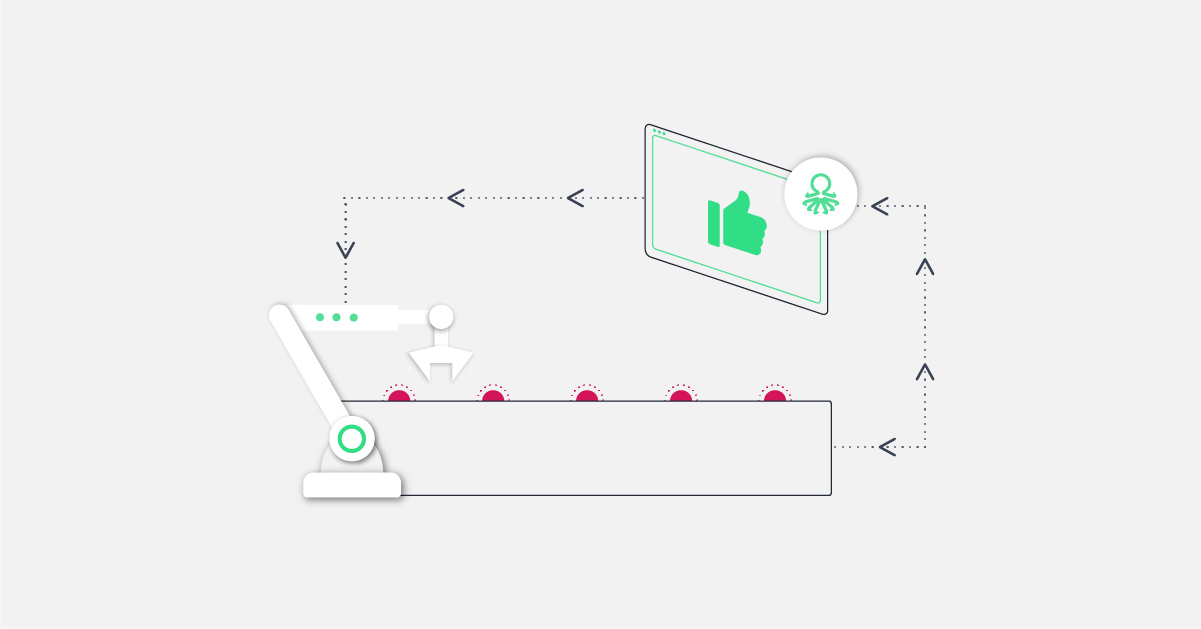

Visual defect detection is a significant use case where AI-powered no-code platforms can be very beneficial. AI models can be trained by manufacturing experts to find production line flaws that are sometimes hard to spot with the naked eye. With AI, manufacturers can spot problems early and address them before they become more serious, which can result in substantial cost savings and enhanced quality assurance.

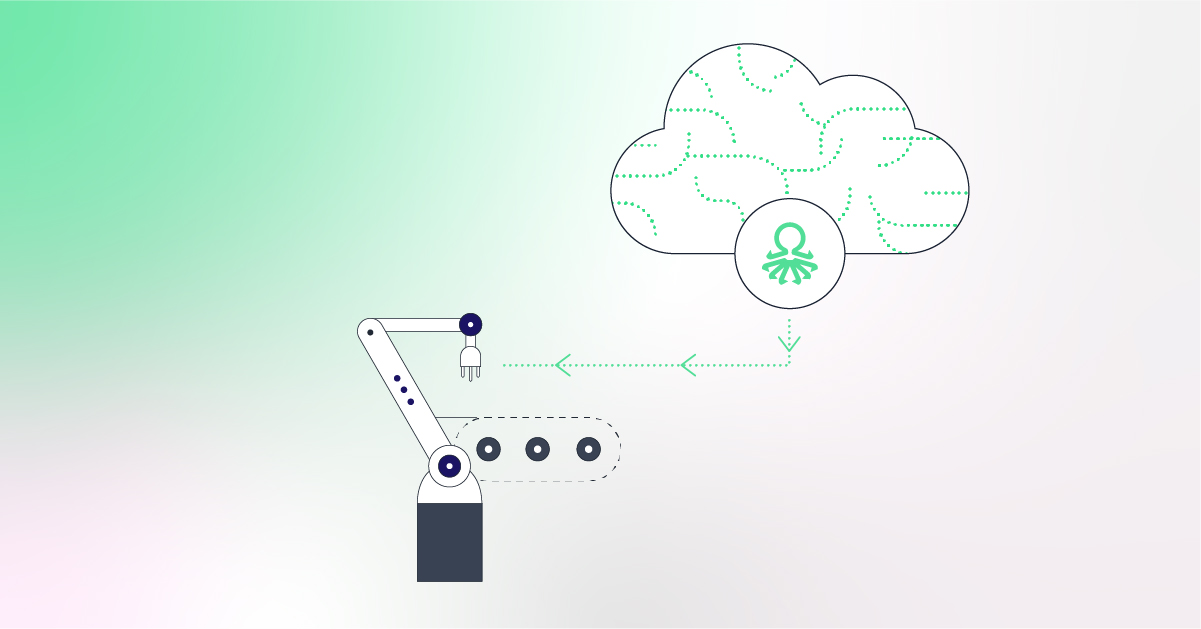

Predictive quality is a further field where AI-powered no-code platforms can be beneficial. AI models can forecast when defects are likely to appear and offer suggestions for preventative maintenance by analyzing data from manufacturing processes. This can aid producers in lowering the probability of flaws and raising the general level of product quality.

No-code platforms with AI capabilities can also aid in production process optimization. AI models can identify areas for streamlining process flows and recommend changes to increase efficiency and decrease waste. Significant expense savings and increases in overall production output may result from this.

Use Cases of Production Optimization with Machine Learning

A few industries that have benefited from the increase in popularity of production optimization software include consumer packaged goods (CPG), semiconductors, automobiles, and pharmaceuticals. The software has the ability to lower manufacturing costs while also improving product quality and productivity.

In the CPG industry, you can use production optimization software, for instance, to check for flawed packaging and ensure that your products arrive at stores in a usable state if you work in the consumer-packaged goods sector. This may reduce manufacturing mistakes and improve total product quality.

Similarly, in the semiconductor industry, production optimization software can enhance the wafer fabrication process to increase output and reduce production costs. Data from the manufacturing process can be analyzed by technology to determine where efficiency improvements can be made.

As another example, production optimization software can assist the pharmaceutical industry in improving the drug creation process. AI-driven no-code systems can analyze clinical trial data to determine which drug candidates have the greatest chances of being approved. As a result, pharmaceutical companies might run fewer fruitless drug trials, saving both time and money.

Vanti’s unique value proposition in Production Optimization Software

Vanti, the industry’s premier AI-powered no-code platform, offers a distinct value proposition by alleviating the problems described earlier and enabling factory leaders and plant managers to improve their operations.

Vanti’s platform stands out because it can spot defects and anomalies in real time and on a scale, helping manufacturers find and fix problems before they influence output or quality. Another great benefit is that Vanti doesn’t require any human input or marking thanks to its self-learning and self-repairing AI. As a result, the optimization method becomes more streamlined and error-free.

The ability of domain specialists to tap into the potential of AI without resorting to coding or other complex technical processes is another key feature of Vanti’s platform. This is especially helpful in production, where there is a chronic lack of trained data scientists and AI specialists. Vanti gives professionals in the manufacturing sector the tools they need to take charge of their processes and generate improved results through the use of artificial intelligence and machine learning.

Conclusion: Investing in the Future with Production Optimization Software

AI-driven no-code software is changing the game for industrial sector executives and managers. These systems allow specialists to focus on their strengths while improving quality assurance, productivity, and cost reduction. By streamlining operations and reducing pressure, professionals in the manufacturing sector have a better chance of meeting their business objectives and remaining competitive.

Improved product quality, greater production efficiency, and cost savings are just a few benefits of using production optimization software across various sectors. As AI and ML technology continues to advance, future production planning software is expected to see significant improvements.

Vanti’s no-code artificial intelligence tool provides a unique solution to the challenges faced by factory bosses and operations managers. With its useful functions, manufacturing experts can streamline their operations and achieve their business goals. By investing in production optimization software like Vanti, professionals in the manufacturing sector can stay ahead of the competition and thrive.