Introduction

The profound quote by Andrew Ng, the founder of Google Brain, “The future of manufacturing will be generated by AI”, is more than a prediction. It’s the clarion call to a new age where generative AI stands on the cusp of a major upheaval in the manufacturing sector. In the coming years, the sheer transformative power of generative AI – its unparalleled capacity to create, innovate and optimize – is set to disrupt this industry on a massive scale.

Generative AI isn’t a nascent concept anymore. It’s a formidable force being rapidly adopted by manufacturers worldwide, with significant pilots and real-world applications being tested and implemented. The reasons for this large-scale adoption are many and varied – from speeding up product development and bolstering quality control, to cutting costs and boosting efficiency.

In this blog post, we will delve into the tremendous capabilities of generative AI in manufacturing and the multitude of benefits it is slated to deliver.

Generative AI in Manufacturing: A New Era

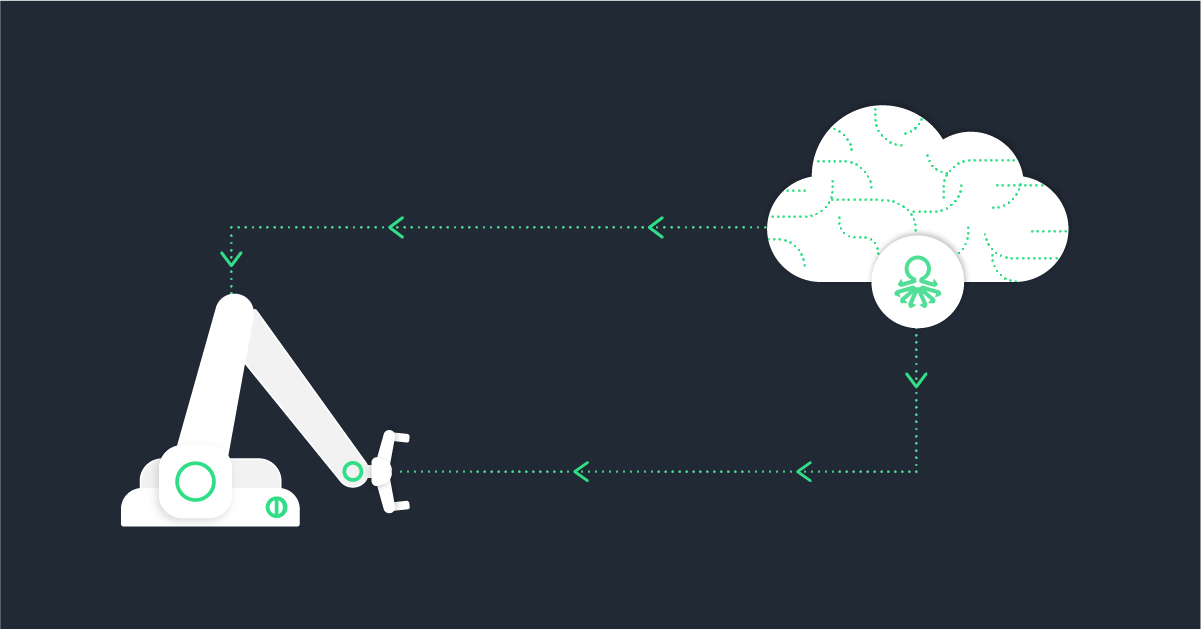

Generative AI, a unique subset of AI, has the power to create new content and ideas. These AI models, known as foundation models, are trained on a vast amount of data, enabling them to understand patterns, learn from them, and generate outputs that mimic the input data.

In the manufacturing realm, generative AI is already making waves. It’s being used alongside high-performance computing to enhance the design of discrete product components, leading to innovative designs that go beyond human imagination. This AI used in manufacturing allows manufacturers to explore various design options quickly and effectively, leading to efficient solutions that minimize cost, mass, materials, engineering design time, and even production time.

Take the automotive industry, for example. Generative AI can be used to design vehicle parts. By inputting desired outcomes such as weight, strength, and cost, the AI can generate numerous design options that meet these criteria, speeding up the design process and resulting in more efficient and cost-effective designs. This is just one of the many applications of generative AI in the manufacturing industry.

The Transformative Benefits of Generative AI in Manufacturing

As discussed earlier, the benefits of generative AI in manufacturing are truly transformative. Think about safety, a paramount concern in any manufacturing environment. Generative AI can analyze vast data sets, predicting potential safety hazards before they occur. It’s like having an extra set of eyes that never blink, constantly watching over the production floor to ensure worker safety.

And it doesn’t stop at safety. Generative AI can create simulation datasets, a kind of virtual testing ground. Manufacturers can experiment, refine, and perfect their processes in this virtual environment before implementing them in the real world. It’s about making every move count, saving time, and optimizing resources.

Speed is another arena where generative AI shines. It can explore ways to manufacture or machine parts faster, fine-tuning production processes to increase speed without compromising quality. This acceleration can give manufacturers a significant edge, helping them get their products to market faster. Generative AI also plays a crucial role in optimizing overall equipment effectiveness (OEE) in factory production environments. It’s like having a crystal ball that predicts equipment failures, allowing for preventative maintenance that reduces downtime and boosts productivity.

Beyond the factory floor, generative AI extends its predictive capabilities to the supply chain. It acts as a control tower, assessing risks from shipping challenges to natural disasters and geopolitical events. This foresight helps manufacturers mitigate risks and ensure a smooth, uninterrupted supply chain.

Consider a manufacturing plant that leverages generative AI to predict machine failures based on historical data. It’s like having a time machine that allows the plant to perform maintenance before the machine breaks down, preventing costly downtime. Similarly, generative AI can optimize the supply chain by predicting demand and adjusting production accordingly. It’s about staying one step ahead, reducing waste, and ensuring timely product delivery.

But generative AI isn’t just about maintaining the status quo; it’s about pushing boundaries. It can help manufacturers innovate and stay competitive. By generating new ideas and designs, manufacturers can create products that are not just efficient and durable, but also resonate with customers. This innovation can lead to increased sales and a stronger market position.

Generative AI in Action: Manufacturing Use Cases

Generative AI is being leveraged across a variety of use cases in the manufacturing sector, providing powerful tools to reimagine traditional processes, enhance efficiency, and innovate for future growth. Let’s explore a few practical applications of this transformative technology.

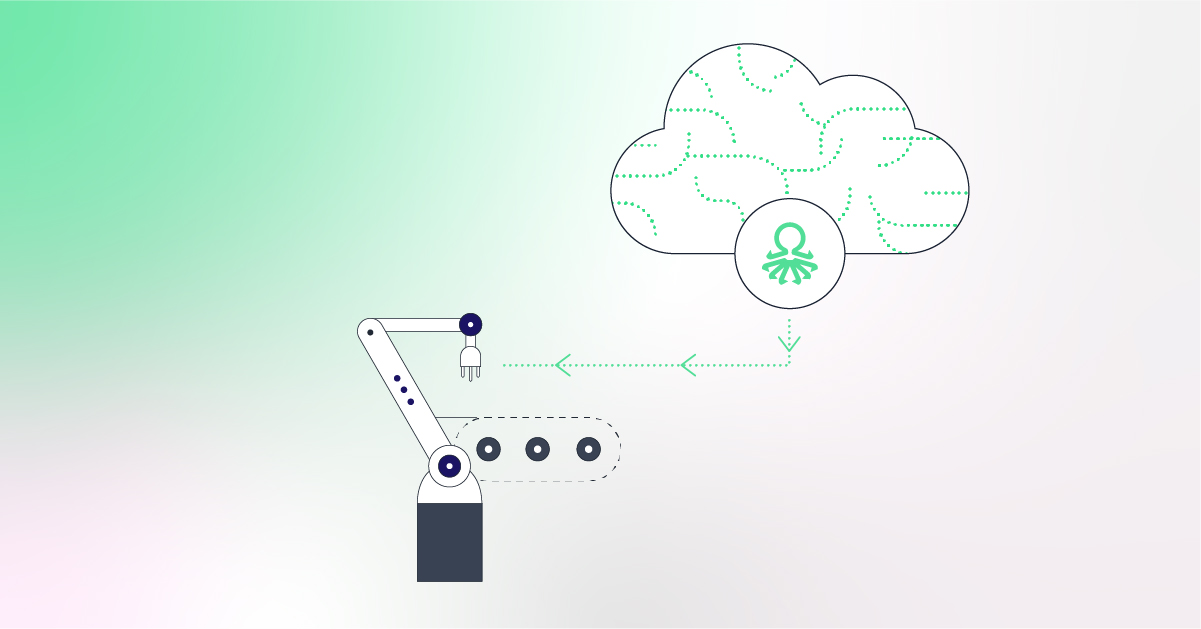

Optimization of Production Processes:

Generative AI can analyze and understand vast amounts of historical production data, predicting potential machine failures or inefficiencies. Using these insights, manufacturers can perform proactive maintenance and optimize production schedules, significantly reducing downtime and enhancing productivity.

Supply Chain Management:

By harnessing the power of generative AI, manufacturers can forecast demand and adjust production accordingly. It also helps in evaluating risks related to shipping, geopolitical events, or natural disasters, thus ensuring a smooth, uninterrupted supply chain.

Product Design and Development:

Generative AI is being used to design innovative products that align with customer needs and market trends. By generating numerous design options based on specified criteria, generative AI speeds up the design process, leading to more efficient and cost-effective product development.

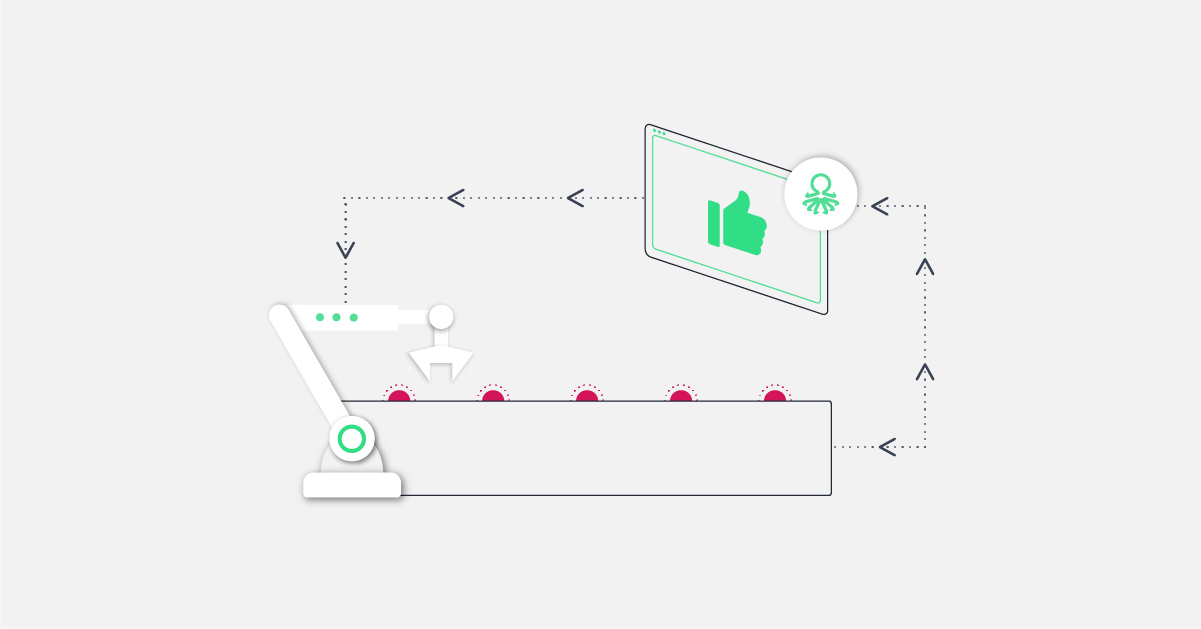

Safety and Quality Assurance:

Generative AI, with its capacity to analyze massive data sets, can predict potential safety hazards and quality issues before they occur. This leads to a safer working environment and high-quality products, ultimately bolstering the brand’s reputation and customer satisfaction.

Training and Knowledge Transfer:

Generative AI models can guide less experienced operators on how to maintain complex production operations efficiently. They can provide high-probability suggestions on equipment input adjustments, maintenance schedules, and even spare parts purchases, thus enabling knowledge transfer and building operational efficiency.

These use cases illustrate the versatility and potential of generative AI in revolutionizing the manufacturing sector. As we move into the future, the adoption and application of this technology will continue to grow, reshaping manufacturing as we know it.

Vanti’s Generative AI: A Game-Changer in Manufacturing

Vanti, a frontrunner in the AI space, offers a unique generative AI-based manufacturing optimization platform that stands as a testament to the power of next-gen AI for manufacturing. This AI-powered platform consolidates all manufacturing data into an insightful knowledge hub, creating a centralized source of information that understands and responds to natural language queries. This feature allows for seamless interaction between the user and the platform, making data exploration a breeze.

Vanti’s platform goes beyond just data consolidation. It simplifies data exploration by providing clear interpretations of complex production behaviors and delivering actionable insights. It takes the guesswork out of data analysis, transforming raw data into meaningful information that can drive decision-making processes in the manufacturing industry. This feature is particularly useful in identifying patterns and trends that might otherwise go unnoticed, enabling manufacturers to make informed decisions that can enhance efficiency and productivity.

The platform’s user-friendly interface allows users to interact with their data through simple, conversational queries. This interactive feature makes the platform accessible to individuals regardless of their technical expertise, democratizing access to data-driven insights. Alongside these interactions, the platform automatically generates detailed visualizations, such as charts and highlights, for a deeper understanding of the data. These visualizations provide a graphical representation of data, making it easier to understand and interpret complex information. This feature enhances the user experience, making data analysis an engaging and insightful process.

One of Vanti’s standout features is its ability to handle the labor-intensive process of data curation. It automatically ensures data quality and consistency, eliminating the need for manual data cleaning and management. This feature allows professionals to focus more on drawing insights and less on the tedious task of data curation. It also reduces the risk of errors that can occur in manual data handling, ensuring that the insights generated are accurate and reliable.

Furthermore, Vanti’s platform is designed to evolve and adapt. It learns from user interactions, continually improving its understanding and response to queries. This ensures that the platform remains effective and relevant, even as the manufacturing industry continues to evolve.

Conclusion: The Path Forward with Generative AI

Undeniably, generative AI has the potential to revolutionize the manufacturing landscape, offering transformative benefits that extend from design optimization to process efficiency and beyond. As we continue to unlock AI’s potential, we stand on the cusp of an exciting new era in manufacturing.

Vanti’s generative AI-based manufacturing optimization platform is a critical tool to aid in this journey, delivering insights, enhancing efficiencies, and powering innovation. But the future beckons us to explore further, to harness the full potential of generative AI, and to reimagine what’s possible.

So, we invite you to join us on this journey of transformation. Let’s collaborate, discover, and push the boundaries of manufacturing with generative AI. Contact Vanti today and let’s shape the future of manufacturing together.