AI-Powered

Manufacturing Insights.

Welcome to Vanti, your ai-powered data wizard, merging all manufacturing data into an insightful knowledge hub that understands and responds to natural language.

Vanti is a sample vendor in: Hype Cycle for Artificial Intelligence, 2023 Hype Cycle for Manufacturing Operations Strategy, 2023

Insights in Minutes,

Not Weeks

Get answers to questions and hypotheses about yield, defects, batches, and processes instantly without lengthy data science projects

Automate Data Engineering Tasks

Let Generative AI wrangle your data for you, joining mismatching tables, curating data sets, and figuring out the inner logic of your data

Fuse it all: ERP, MES, PLM, SCADA, Sensors…

Manufacturing data takes many forms, utilize all of them to get an understanding of your actual process

Ask Questions, Gain Insights

CHAT

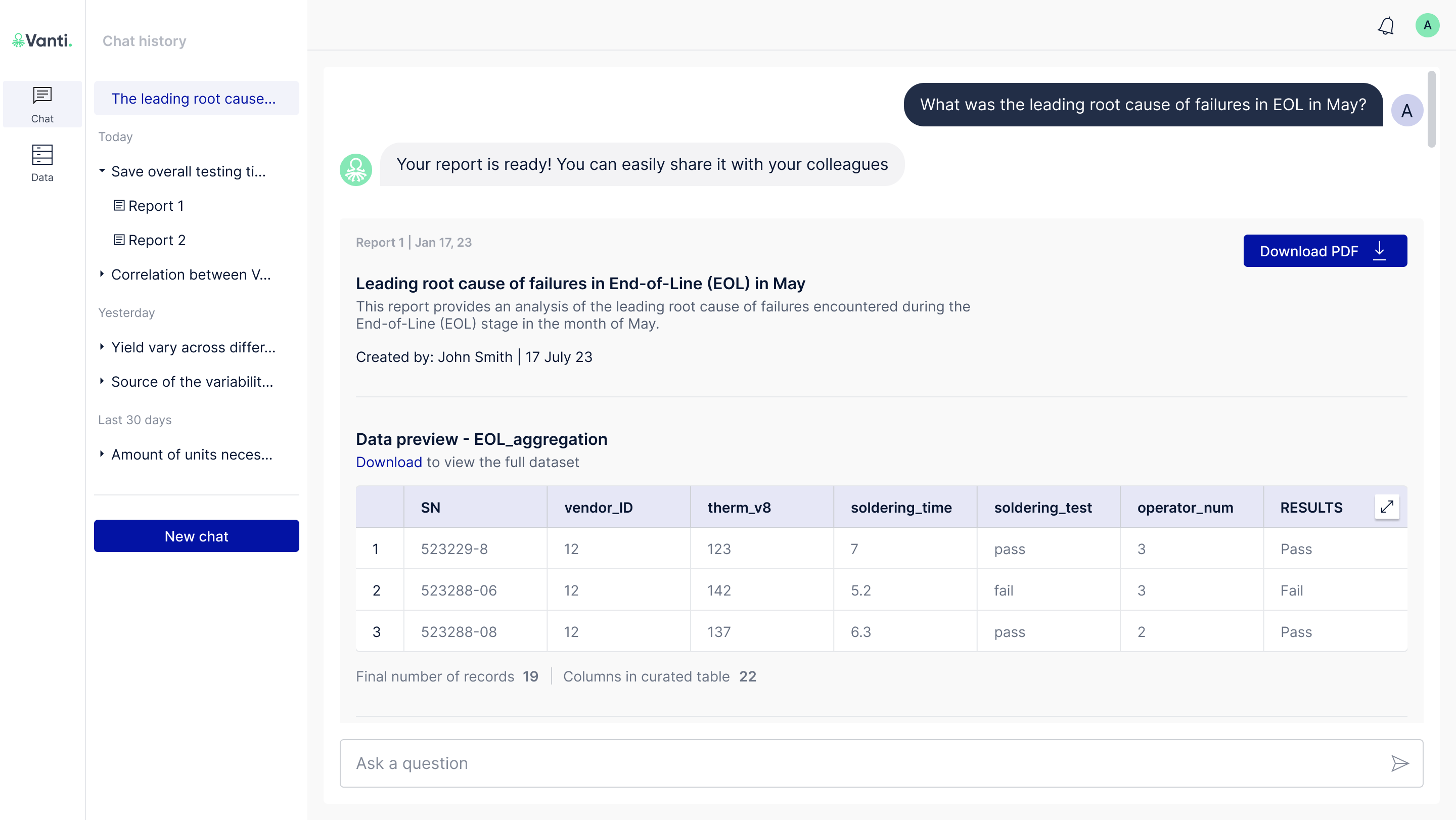

Vanti’s Manufacturing Analytics is a robust solution for today’s plant professionals. With its ability to fuse manufacturing data from multiple sources, Vanti offers an automated, intuitive, manufacturing insights platform. Using advanced natural language processing, Vanti provides clear interpretations of complex production behaviors and delivers actionable insights. This simplifies your data exploration, making it as easy as having a conversation.

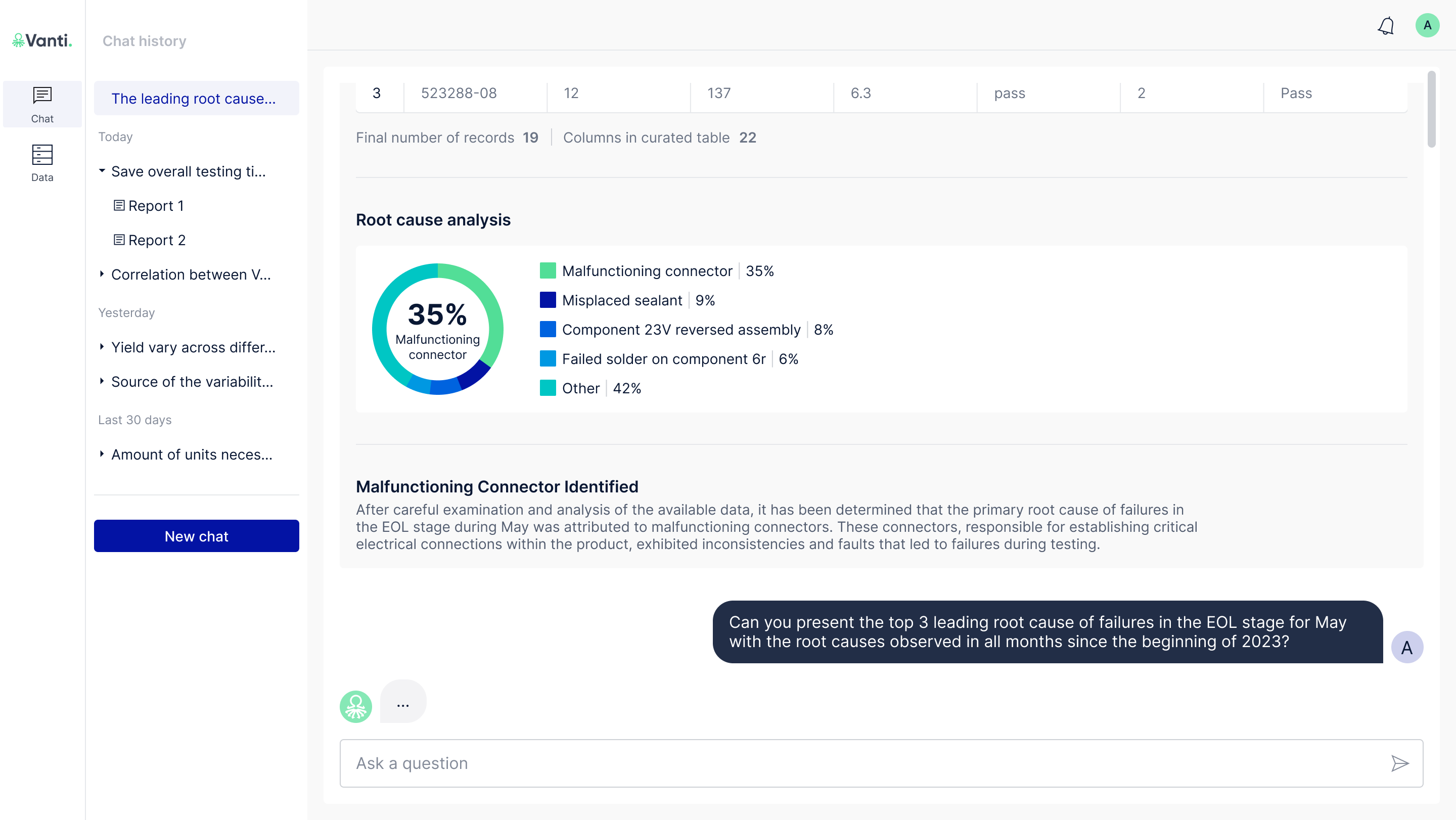

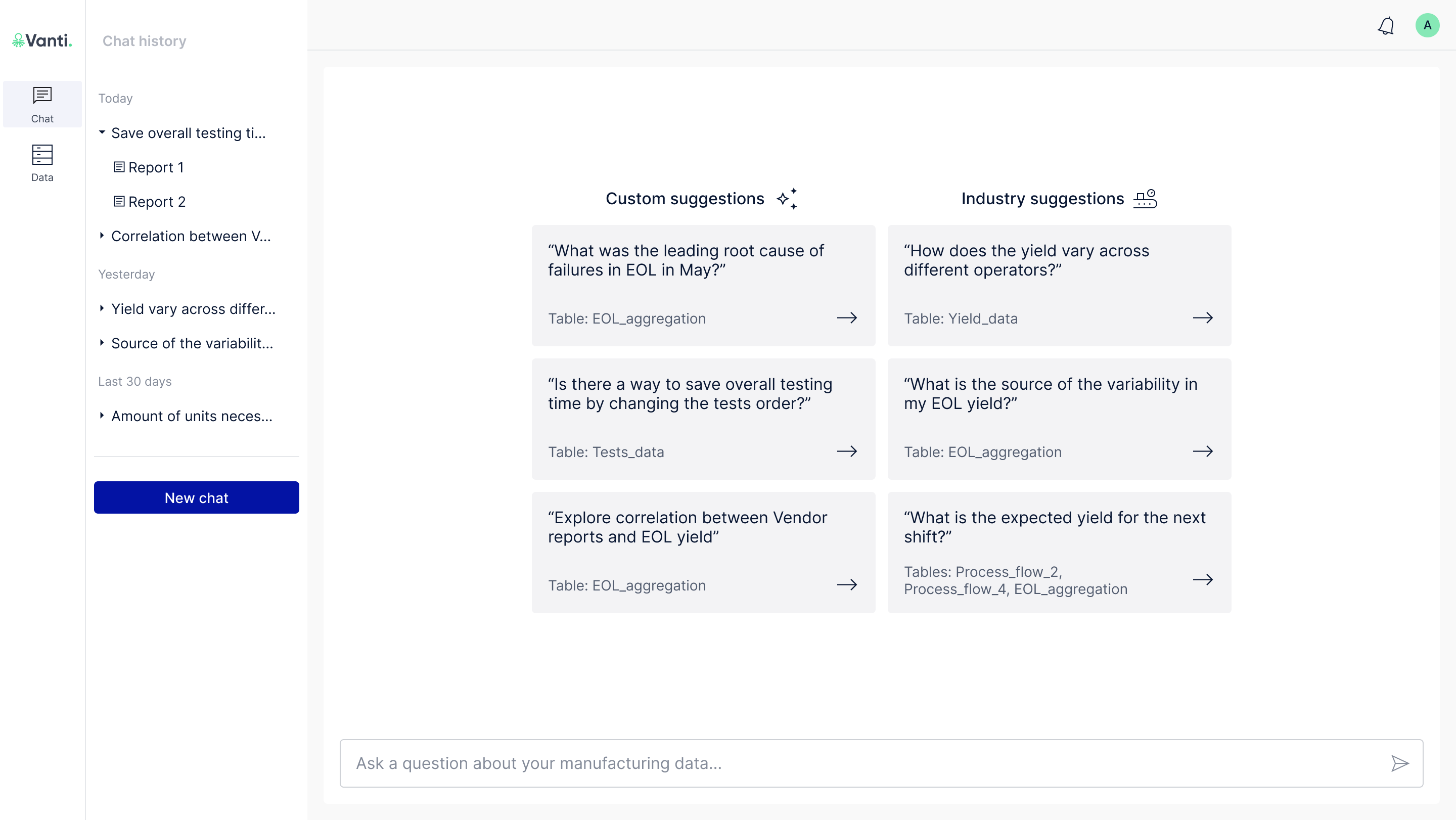

Natural Language Interface

Vanti allows users to interact with their data through simple, conversational queries. Alongside these interactions, the platform automatically generates detailed visualizations, such as charts and highlights, for a deeper understanding of the data. All of this is incorporated into an intuitive user interface, providing easy navigation and operation, regardless of your technical expertise.

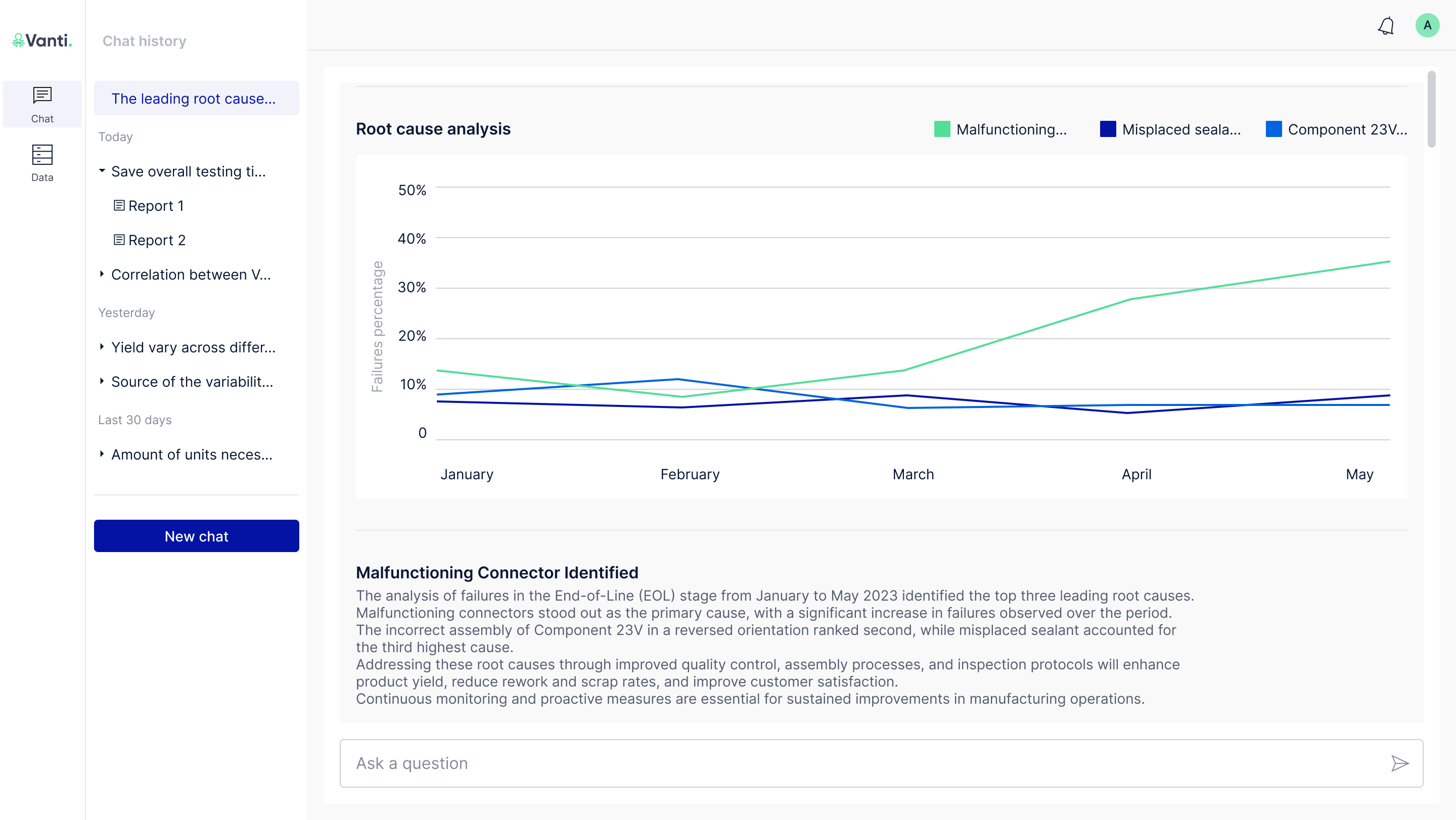

Understand Plant Behavior

Through Vanti’s sophisticated manufacturing analytics, professionals can gain a comprehensive understanding of plant behavior. The platform translates complex production data into clear, actionable insights, enabling smarter decision-making.

Insight Explainability

Vanti takes insight delivery to the next level. Not only does it generate detailed visualizations like charts and highlights, but it also provides an in-depth understanding of the data. With Vanti, you can delve deeper into your insights, and conveniently share or download reports to collaborate with other professionals.

Rapid Hypothesis Testing

With Vanti, manufacturing professionals can swiftly examine their theories about production behavior. They can either submit a query using everyday language or select a pre-defined question based on domain expertise. This allows them to gain instant insights without the complexity of building intricate data models.

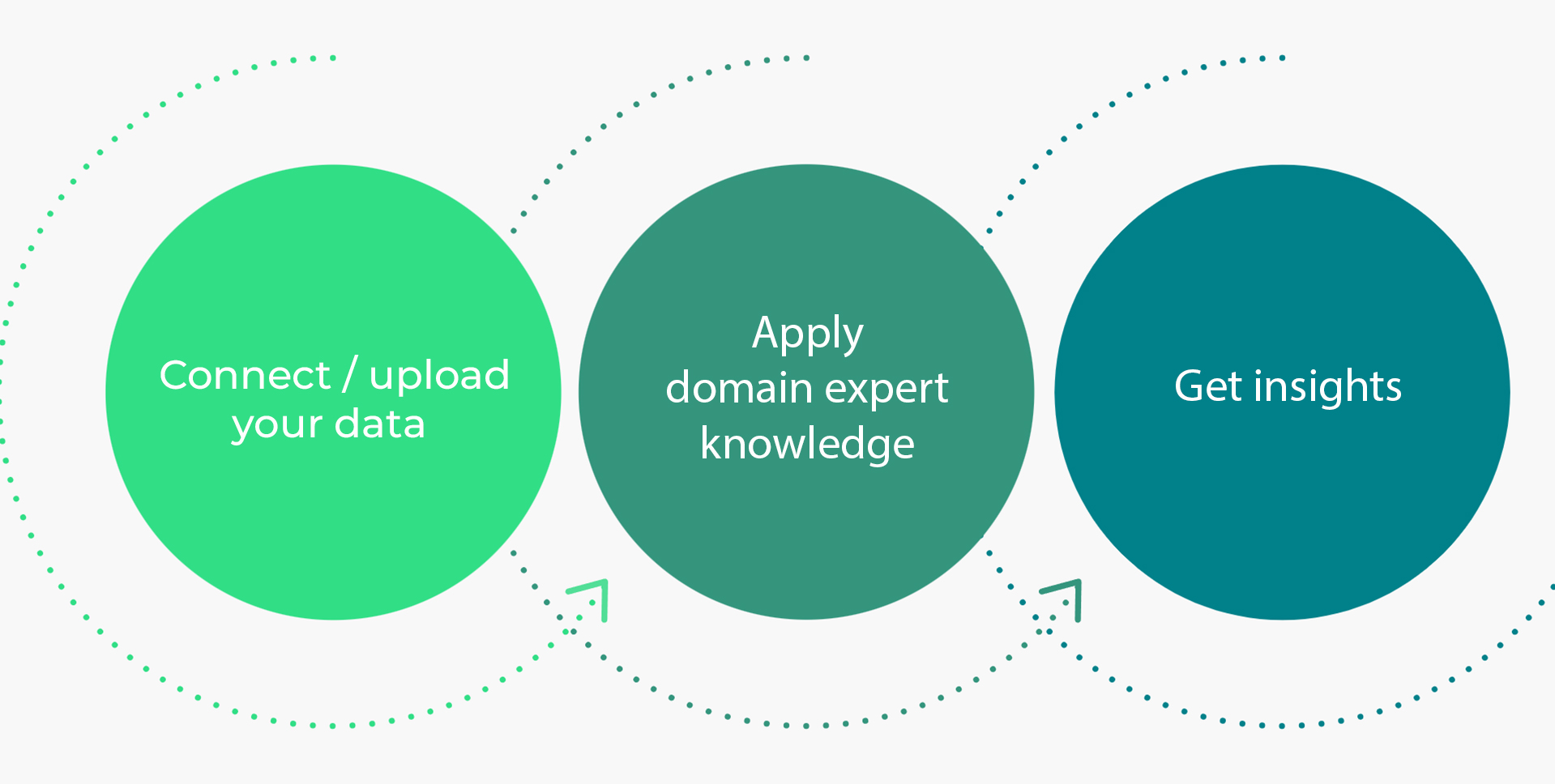

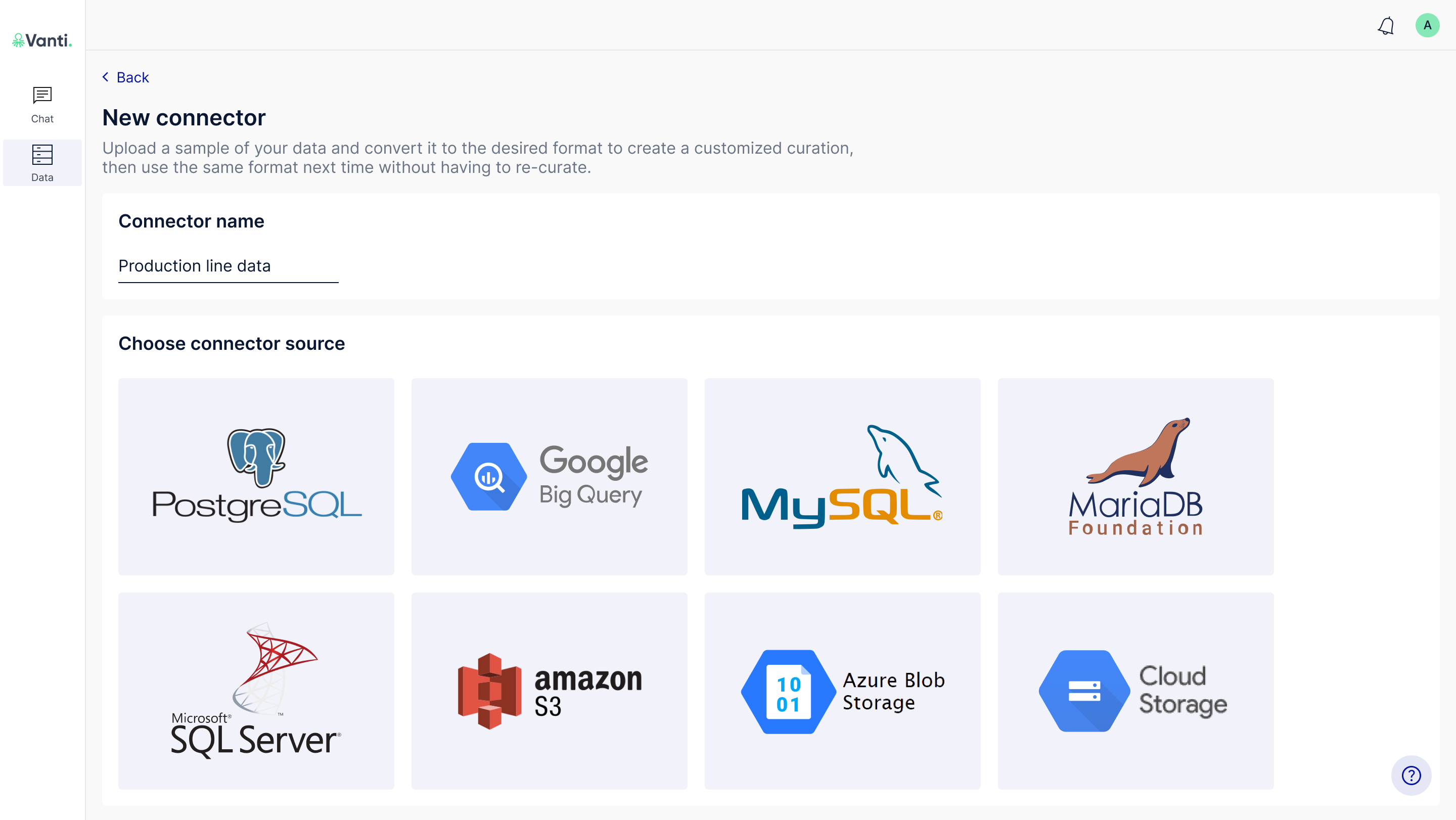

CURATE

Data Fusion and Curation

Vanti handles the labor-intensive process of data curation, automatically ensuring data quality and consistency. This allows professionals to focus more on drawing insights and less on cleaning and managing data.

In hours, not months.

Data Integrations

Vanti integrates manufacturing data from multiple sources into a single platform, utilizing sophisticated data fusion techniques. It also automates the data curation process, ensuring data quality and consistency.

Streamlined Data Engineering

Vanti’s automation and intuitive interface dramatically reduce the duration of data engineering projects. What used to take weeks can now be accomplished in minutes, freeing up valuable time and resources.